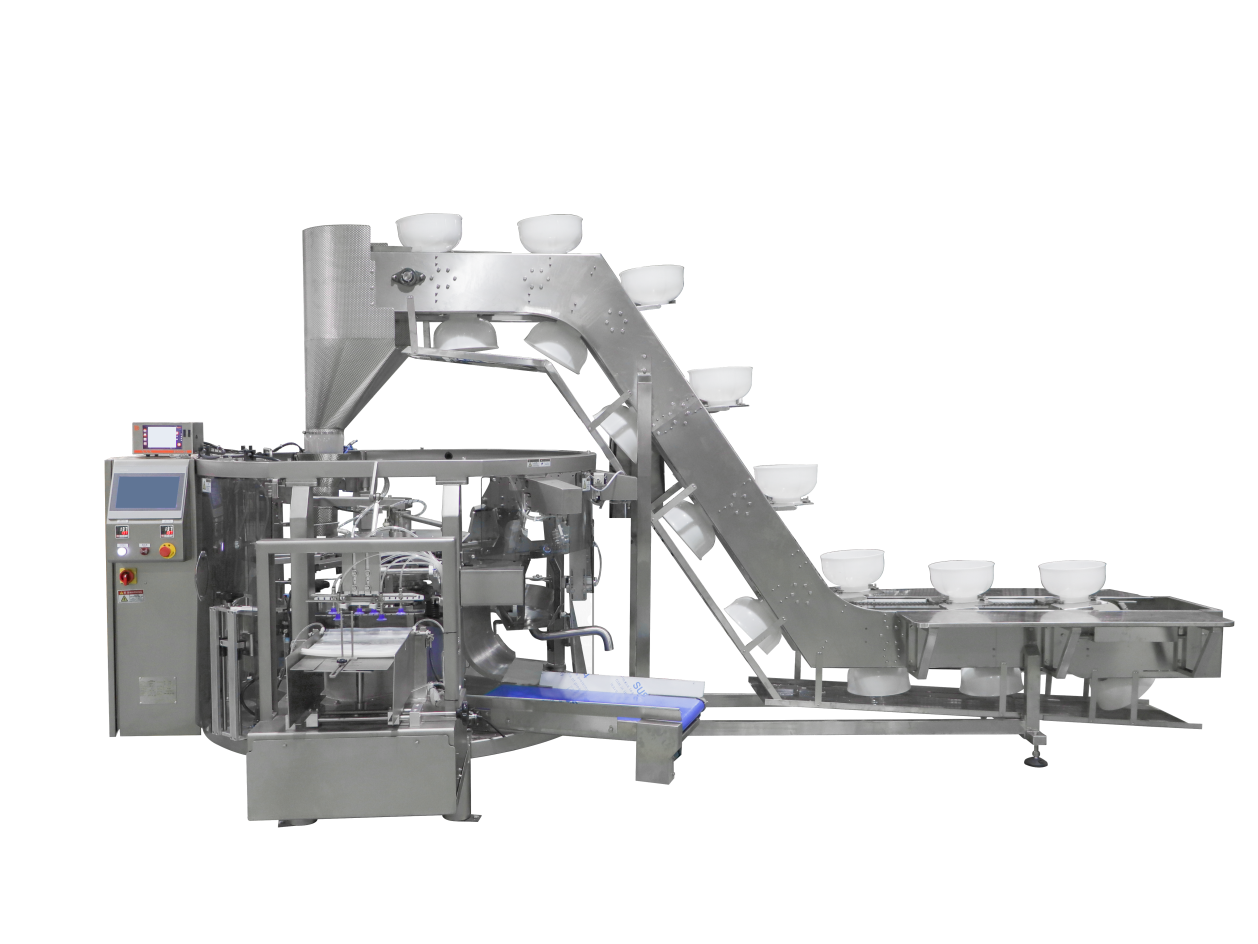

Pre-Made Pouch Packaging Solution for Meat Products with Bowl Elevator Feeding

Introduction

Packaging fresh chicken requires a solution that ensures cleanliness, efficiency, and proper handling of heavy loads. For medium-capacity production environments like butcher shops, food processing plants, or poultry product distributors, a semi-automated system combining manual weighing, bowl-type elevator feeding, and a pre-made pouch packaging machine is a practical and reliable solution. This setup is especially ideal for packing 2.5kg portions of fresh or marinated chicken into durable pouches.

System Configuration

The system consists of a pre-made pouch packaging machine, a bowl-type elevator, and a manual weighing step. Operators first weigh 2.5kg portions of chicken and place them into the bowls of the elevator. The elevator gently lifts the product and transfers it into the pouch filling station of the packaging machine. The packaging machine then automatically opens each pre-made pouch, fills it with the chicken, seals it tightly, and discharges the finished package.

Working Principle

1. Manual Weighing: Workers accurately measure 2.5kg of chicken pieces per portion.

2. Feeding via Bowl Elevator: Chicken is loaded into the bowl-type elevator, which lifts it gently to avoid damage or contamination.

3. Pouch Opening and Filling: The packaging machine picks up the pouch, opens it with vacuum suction, and fills it with chicken.

4. Sealing: The machine then performs heat sealing to ensure airtight and leak-proof closure.

5. Discharge: Finished pouches are conveyed for secondary packaging or cold storage.

Advantages

Gentle Product Handling: Bowl elevators minimize damage to the chicken and prevent contamination.

High Packaging Accuracy: Manual weighing ensures precise portion control for wholesale or retail needs.

Flexible Pouch Compatibility: Supports stand-up pouches, zipper bags, and flat pouches.

Hygienic and Easy to Clean: All contact surfaces are made of food-grade stainless steel.

Labor-Efficient Workflow: Combines human flexibility with automation, increasing productivity without sacrificing control.

Applications

This packaging solution is suitable for:

Fresh or marinated chicken pieces (wings, drumsticks, breast portions)

Duck or other poultry products in fixed weight formats

Ready-to-cook meat packs for wholesale or supermarket supply

Conclusion

The pre-made pouch chicken packaging solution offers an efficient and hygienic method for packing heavy and irregular-shaped poultry products. By combining manual weighing with automated filling and sealing, this setup ensures accurate portioning, tight sealing, and reliable performance. It is the perfect solution for mid-sized food processors seeking to upgrade from manual packing to a semi-automated system without sacrificing flexibility or hygiene.

Get the latest price? We'll respond as soon as possible(within 12 hours)