The Science Behind Spicy Strips Packaging: From Material Selection to Automation Solutions

Introduction

Spicy strips, also known as spicy gluten snacks, are among the most popular ready-to-eat foods in Asia and beyond. Characterized by their chewy texture, rich aroma, and bold flavors, these snacks require special attention during packaging to maintain freshness, hygiene, and shelf stability. With rising global demand for convenient snack foods, the packaging process of spicy strips has evolved from manual sealing to semi-automatic and fully automated systems.

Why Spicy Strips Packaging Requires Special Consideration

Unlike dry snacks such as chips or nuts, spicy strips contain oil, seasoning, and moisture, which makes them more sensitive to oxidation, microbial growth, and packaging material compatibility. A suitable packaging system must ensure:

1.Oil and moisture resistance to prevent leakage or delamination.

2.High sealing integrity to avoid contamination.

3.Efficient packaging throughput for large-scale production.

4.Convenient opening and portion control for consumers.

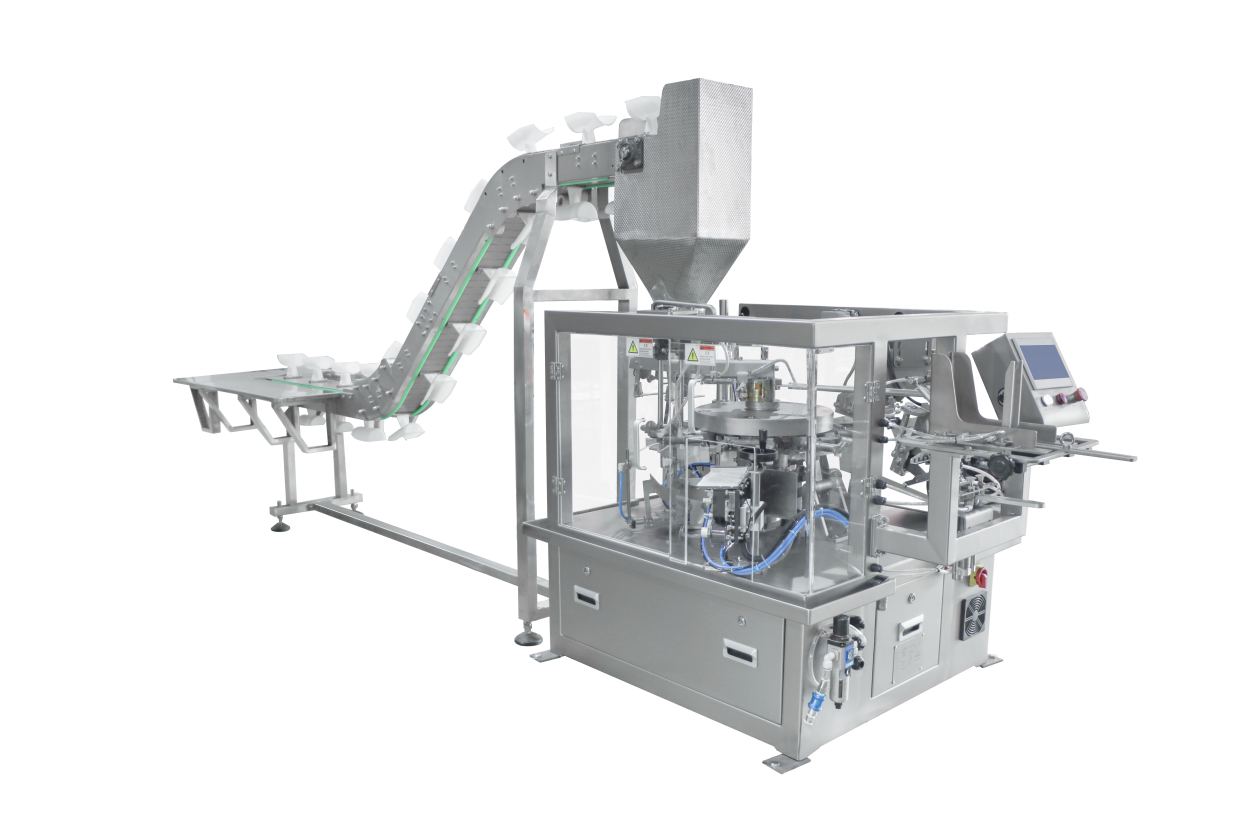

To meet these requirements, many food producers now use premade pouch packaging machines paired with chain-plate bucket elevators that allow for controlled, hygienic, and efficient manual feeding.

The Modern Packaging Process

The modern spicy strip packaging process combines manual precision with automated consistency. Typically, workers place the spicy strips into a chain-plate bucket elevator, which carefully lifts the product to prevent damage or sticking caused by oil. The product is then transferred into a premade pouch packaging machine, where pouches are automatically opened, filled, and sealed. This setup keeps the product hygienic, reduces contamination risks, and ensures a clean sealing finish.

The system allows for flexible packaging formats such as stand-up or pillow pouches, adapting easily to various product sizes. With sensors and temperature-controlled sealing jaws, each bag is properly formed and sealed with minimal waste. The combination of manual feeding and automatic filling provides an ideal balance—operators ensure product quality during loading, while the machine handles the precision and speed of packaging.

Common Packaging Types for Spicy Strips

Packaging Type | Material Composition | Advantages | Typical Applications |

Pillow Bags | BOPP/CPP or PET/PE laminated film | Cost-effective, compatible with horizontal sealing, suitable for high-speed packaging | Standard retail packaging for small spicy strip portions |

Flat Pouches | PET/PE or PET/AL/PE | Strong barrier against oil and oxygen, ideal for single-serve snacks | Budget snack packs, convenience stores |

Stand-up Pouches | PET/VMPET/PE or PET/AL/PE | Premium appearance, reclosable options available, excellent shelf display | Mid-range to premium spicy strip brands |

Vacuum Bags | Nylon/PE (PA/PE) | Extends shelf life by minimizing oxidation and flavor loss | Bulk packaging, export markets |

Material and Barrier Considerations

The selection of packaging film is essential for maintaining flavor stability and shelf life. Spicy strips contain oil and chili-based seasonings, which may migrate through unsuitable materials. Therefore:

Aluminum foil laminations (e.g., PET/AL/PE) offer the best light and oxygen barrier.

VMPET structures provide similar protection but with lower cost and better recyclability.

For smaller retail packs, BOPP/CPP films remain a cost-efficient solution with good sealing performance.

Additionally, anti-static and heat-resistant properties are important to prevent product adhesion and ensure smooth sealing during high-temperature operations.

Hygiene and Safety in Snack Packaging

Because spicy strips are high in oil content, maintaining clean packaging conditions is critical. The chain-plate bucket elevator is typically made of food-grade stainless steel or PP material, allowing easy cleaning and minimizing residue buildup.

The premade pouch machine can also integrate dust collection and nitrogen flushing systems to reduce oxidation and keep the packaging area clean.

The Role of Automation in Spicy Snack Packaging

Automation in spicy snack packaging focuses on improving efficiency, hygiene, and consistency. The premade pouch machine works seamlessly with the chain-plate elevator, maintaining a steady product flow and accurate filling weight. Automatic pouch handling, sealing, and date coding make the process faster and more uniform, while reducing human contact with food.

This semi-automated solution gives manufacturers flexibility to adjust pouch types and sizes, whether for small retail packs or bulk snack bags. By combining gentle product handling with precise sealing technology, it ensures that each package of spicy strips remains fresh, clean, and visually appealing—meeting both safety standards and modern packaging expectations.

Case Insight: Transitioning from Manual to Semi-Automatic Packaging

A mid-sized snack company in Southeast Asia recently shifted from manual sealing to a premade pouch packaging line. Using a chain-plate elevator for manual feeding, operators could maintain careful product arrangement while the packaging machine handled sealing and date coding.

The transition increased production efficiency by over 40%, reduced packaging waste, and improved product hygiene without losing flexibility in snack variety and pouch size.

Conclusion

Spicy strips packaging reflects the growing sophistication of the snack food industry. By integrating manual feeding with automated sealing, manufacturers achieve a perfect balance between efficiency, hygiene, and cost control.

As consumer demand for ready-to-eat, high-quality snacks expands globally, semi-automated solutions like the premade pouch machine with chain-plate elevator feeding will continue to shape the next generation of spicy snack packaging.

Get the latest price? We'll respond as soon as possible(within 12 hours)