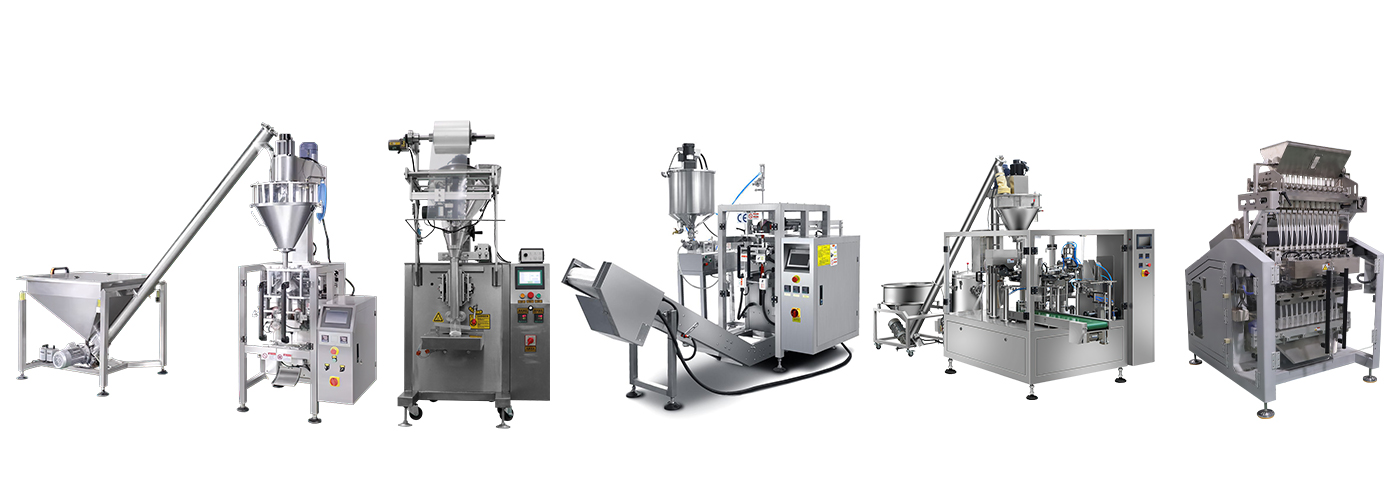

Vertical packing machine with Measuring cup feeder

Vertical packaging machine equipped with a measuring cup weighing system, designed for precise and efficient packaging of granular or powdered products. The machine, constructed with stainless steel for durability and hygiene, automates the entire packaging process.

Details

Vertical packing machine with Measuring cup feeder

| Bag width | 50-200mm | Weight range | 30-1000g | |

| Film material | OPP/CPP.OPP/PE/PET | Functions | Filling,Labeling,Sealing | |

| Speed | 30-75bags/min | Machine weight | 300KG | |

| Power | 220V 50/60Hz 2.2KW | Packing items | Flour,milk powder,coffee powder detergent powder etc | |

| Machine size | 740*940*1750mm(L*W*H) | Film roll diameter | Max 300mm | |

| Machine material | Stainless steel 304/316L for option | |||

Vertical packaging machine equipped with a measuring cup weighing system, designed for precise and efficient packaging of granular or powdered products. The machine, constructed with stainless steel for durability and hygiene, automates the entire packaging process.

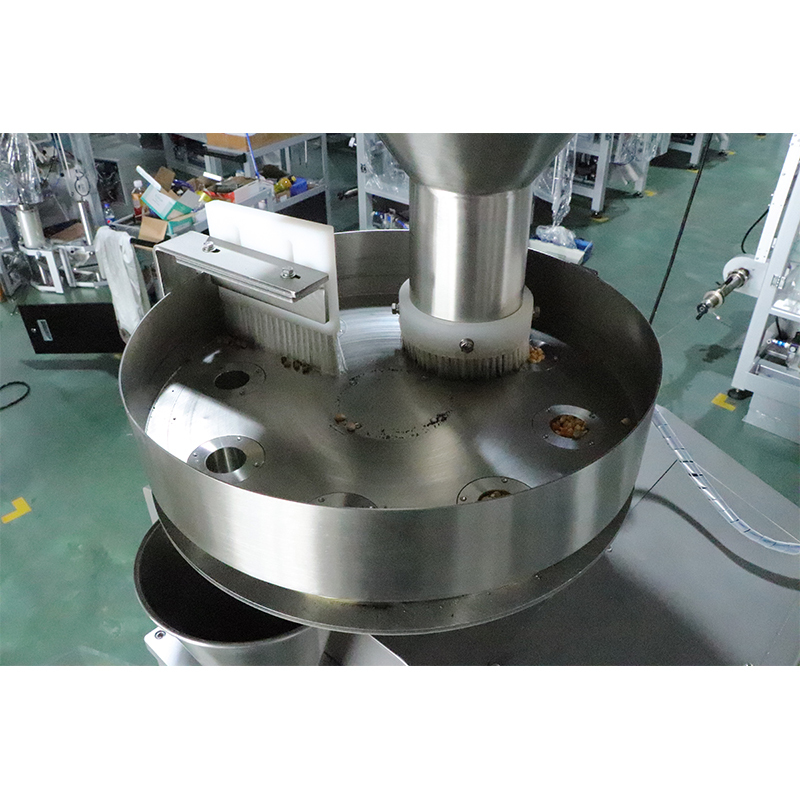

It features a hopper at the top for material input, which then utilizes a measuring cup mechanism to ensure accurate weight control for each package. The machine forms, fills, and seals bags vertically, making it ideal for packaging items such as sugar

Packaging Process:

Material Feeding: The process begins with the raw material, such as sugar, being poured into the hopper at the top of the machine. The hopper stores the material and feeds it into the measuring cup system.

Weighing: As the material enters the measuring cup, it is precisely weighed to ensure each package contains the exact amount. This step is crucial for maintaining consistency and accuracy in product packaging.

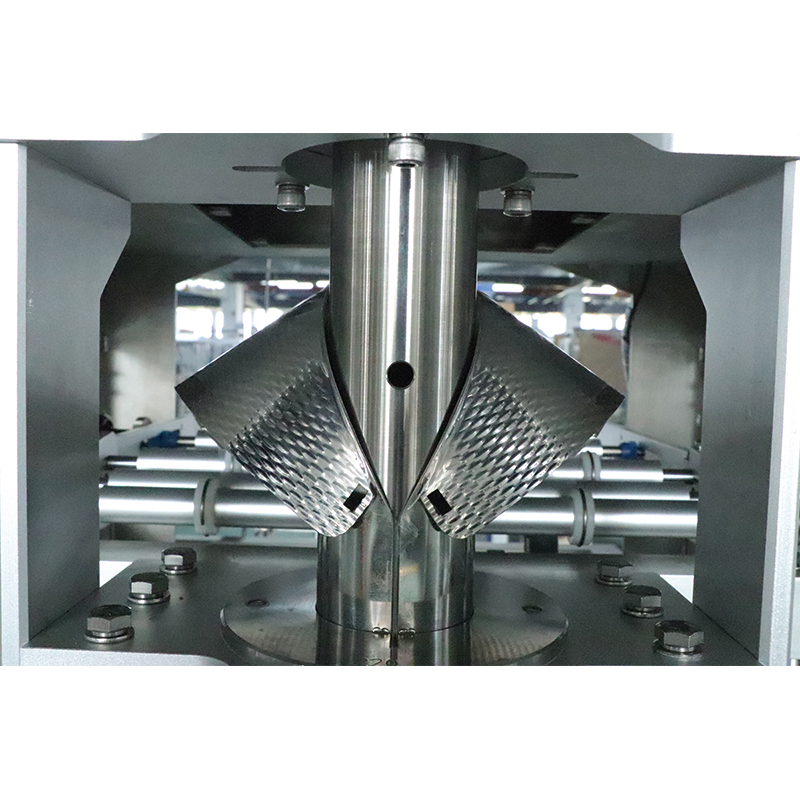

Forming the Bag: Simultaneously, a roll of packaging film is fed through the machine, where it is formed into a vertical tube. The machine seals the bottom of this tube to create an open bag ready for filling.

Filling: Once the material in the measuring cup reaches the predetermined weight, it is released into the formed bag below. The machine ensures a swift and accurate transfer of the material to prevent spillage and maintain cleanliness.

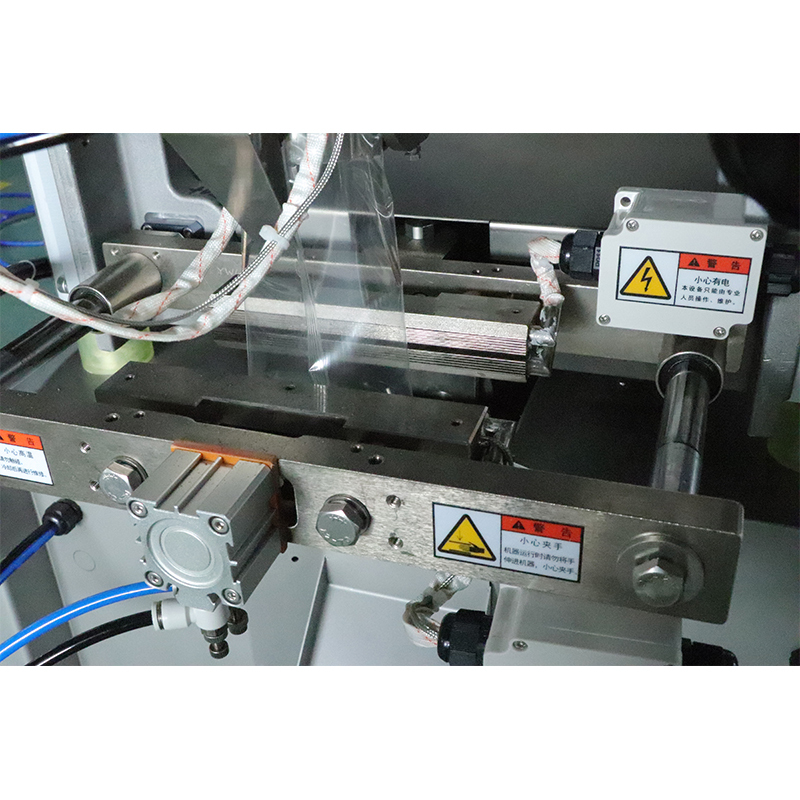

Sealing and Cutting: After filling, the top of the bag is sealed, and any excess film is trimmed. The machine then cuts the sealed bag from the film roll, completing the packaging process for one unit.

Output: The finished, sealed package is then discharged from the machine, ready for distribution.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)