Liquid Sachet Packaging: Efficiency, Safety, and Market Applications

Introduction

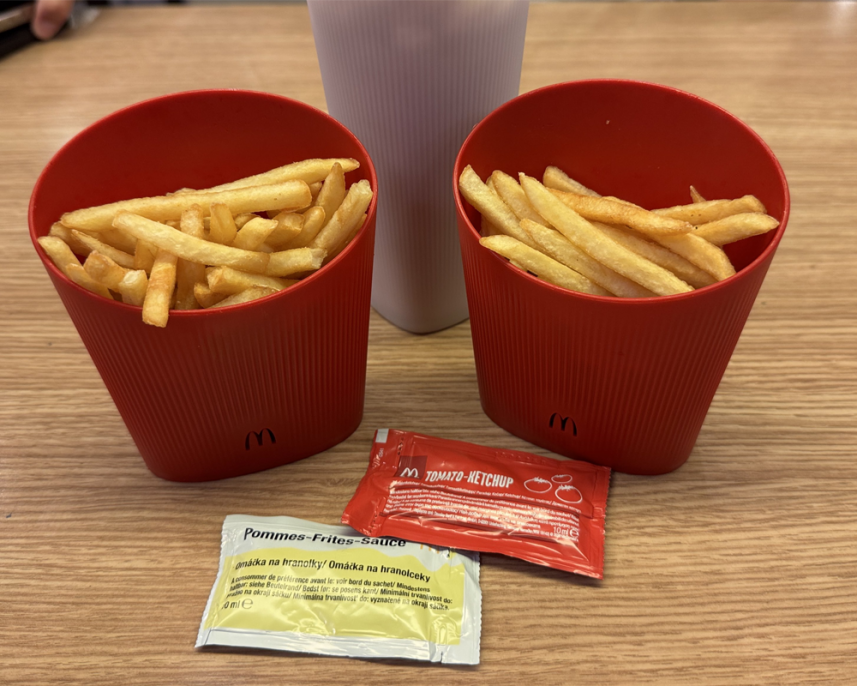

Liquid sachet packaging has become one of the most widely adopted solutions in the food, beverage, cosmetics, and pharmaceutical industries. From sauces, condiments, and juices to shampoos, lotions, and medical liquids, the use of small sachets ensures product safety, precise portioning, and convenient transportation. As global demand for portable and single-use products continues to rise, sachet packaging provides a cost-effective and practical choice for manufacturers worldwide.

Why Sachet Packaging for Liquids?

Unlike rigid bottles or jars, sachet packaging uses flexible film materials that reduce packaging weight, save space during logistics, and lower production costs. For industries where hygiene, shelf life, and accurate dosing are critical, sachets offer strong sealing performance and excellent product protection. Moreover, the adaptability of modern packaging machines allows a wide range of films—from laminated plastics to eco-friendly biodegradable materials—supporting sustainability goals while ensuring product quality.

Key Functions of Liquid Sachet Packaging

1. Product Protection–High-quality barrier films prevent leakage, oxidation, and contamination.

2. Portion Control–Each sachet delivers a fixed dose, reducing waste and improving consumer convenience.

3. Extended Shelf Life–Heat sealing and multilayer materials ensure stability for sensitive liquids.

4. Hygiene and Safety–Single-use sachets minimize cross-contamination risks in food and pharmaceuticals.

5. Cost Efficiency–Lightweight and compact, sachets reduce transportation and storage expenses.

Packaging Process and Machinery

Modern sachet packaging machines integrate multiple technologies to achieve precise filling and sealing. Liquid dosing is typically handled by piston pumps or peristaltic pumps, ensuring high accuracy for both low-viscosity products like juices and high-viscosity products like syrups or lotions. Machines form the sachet directly from film rolls, fill the liquid, and seal it using heat-sealing jaws, guaranteeing tight closure. Options such as tear notches, spouts, or Euro-holes can be added for consumer convenience.

For industries requiring labeling, coding, or batch tracking, sachet machines can be equipped with printers and automatic labeling systems, ensuring compliance with international traceability standards. In high-volume production lines, integration with conveyors, secondary packaging, and carton sealing machines ensures smooth workflow and improved efficiency.

Sachet Design and Market Formats

Liquid sachets are available in various styles, depending on the product and consumer needs:

Three-side seal sachets—Compact and widely used for sauces, shampoo, and medical liquids.

Four-side seal sachets—Provide a more uniform shape and enhanced sealing strength.

Stick packs—Slim design for beverages, energy gels, and single-dose syrups.

Back seal sachets—Secure, airtight packaging with a clean vertical seal at the back, ideal for powders, granules, and single-serve products.

Common Packaging Materials

The choice of packaging material plays a critical role in ensuring both product safety and shelf stability. Below is a comparison of commonly used materials for liquid sachets:

Material Type | Advantages | Limitations | Typical Applications |

PET/PE Laminates | High clarity, strong sealing, resistant to leakage | Limited recyclability | Sauces, juices, liquid detergents |

Aluminum Foil Laminates | Excellent barrier against oxygen, light, and moisture | Less eco-friendly, higher cost | Pharmaceuticals, dairy concentrates |

Paper/Poly Films | Eco-friendly, cost-effective | Lower barrier properties for liquids | Condiments, instant drink mixes |

Biodegradable Films | Environmentally sustainable, growing demand | Higher production cost, limited shelf-life | Organic beverages, natural cosmetics |

Future Outlook

As consumer lifestyles shift toward portability, hygiene, and eco-friendly packaging, liquid sachets will continue to play an essential role in global markets. Advances in biodegradable films, smart labeling, and machine automation will further expand their applications across industries. Whether in food service, personal care, or pharmaceuticals, sachet packaging remains a practical and future-ready choice for liquid products.

Get the latest price? We'll respond as soon as possible(within 12 hours)