Bath Bomb Packaging Explained: A Science-Based Guide to Heat Shrink Wrapping and Shrink Tunnels

Introduction

Bath bombs are visually appealing, fragrance-rich products designed to dissolve rapidly in water—yet those same characteristics make them unusually demanding to package. Their formulas often contain moisture-sensitive ingredients (such as sodium bicarbonate and citric acid), aromatic oils that can volatilize or migrate, and pigments that can scuff or stain when handled. In addition, bath bombs are brittle compared with many solid consumer goods, so even minor vibration or compression during transport can lead to chipping and dusting. For these reasons, bath bomb packaging is less about “wrapping something for retail” and more about controlling humidity exposure, surface protection, and distribution durability from the moment the product leaves production.

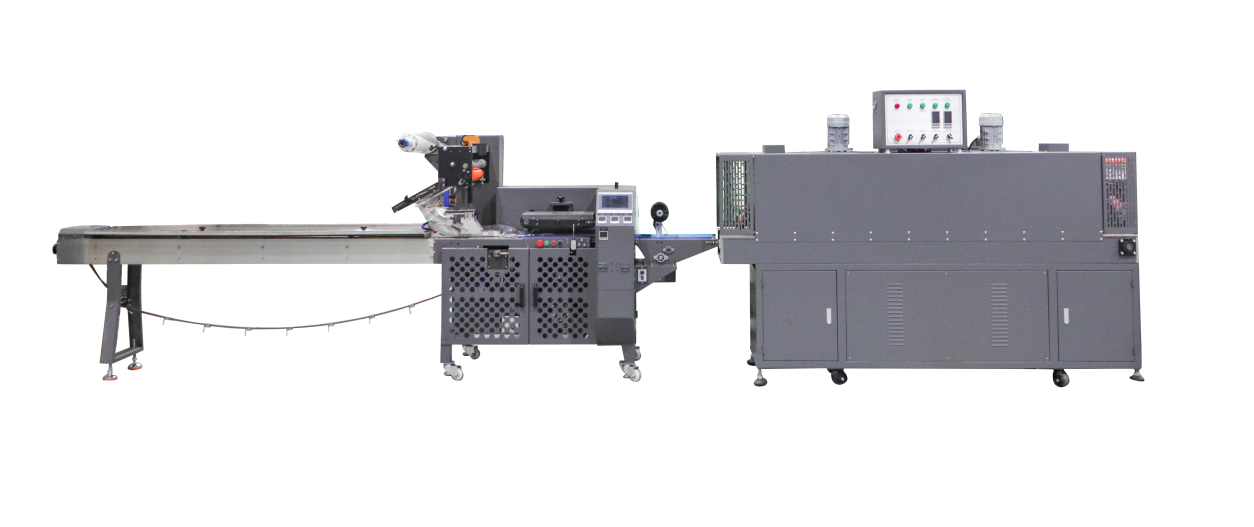

One widely used approach for individual or multi-pack bath bombs is a heat shrink wrapping machine paired with a heat shrink tunnel. This setup produces a tight, transparent protective layer that reduces friction, limits moisture contact, and improves the product’s resistance to handling damage. This article explains how and why this system works, what materials are typically used, and which packaging decisions matter most for quality and shelf stability.

Why Bath Bombs Need Specialized Packaging

Bath bombs can start reacting prematurely if they absorb moisture from the air, especially in humid climates or during seasonal swings. Even without visible reaction, moisture uptake can soften edges, reduce fizz performance, and cause scent changes over time. At the same time, bath bombs are “aesthetic-first” products: consumers expect clean surfaces, crisp colors, and intact shapes. Powdering, micro-cracks, and scuffing can make products look old even when they’re fresh. Packaging therefore has a dual mission—protecting the chemistry inside and preserving the appearance outside.

In retail environments, bath bombs also face constant handling. Customers pick them up, compare scents, and put them back. Unprotected bombs can pick up fingerprints, dust, and cross-fragrance contamination. Shrink wrapping provides a hygienic barrier that helps prevent surface contamination while still allowing product visibility.

Understanding Heat Shrink Wrapping for Bath Bombs

A typical shrink-wrapping process uses center-fold film and creates a sealed wrap around the product. In practical terms, the bath bomb is guided into the film, longitudinal sealing forms the back seal, and end sealing/cutting creates individual packs. After that, the product enters a shrink tunnel, where controlled hot airflow causes the film to contract evenly, conforming to the bath bomb’s shape.

What makes this combination particularly suitable for bath bombs is the balance between gentle handling and strong surface protection. Bath bombs can be unstable on conveyors because they are round, uneven, or dusty. A well-designed infeed and product spacing method helps prevent rolling and collision before sealing. Once wrapped, the film acts like a “protective skin,” reducing abrasion and stabilizing the product for downstream handling and shipping.

How the Heat Shrink Tunnel Impacts Quality

The shrink tunnel is not simply a heating box; it is a controlled environment where temperature, airflow, and dwell time determine the final appearance and performance of the packaging. Too much heat can cause film thinning, wrinkles, or uneven shrink lines. Too little heat leaves loose packaging that looks untidy and offers weaker protection. The goal is to achieve a consistent, tight finish without overheating the bath bomb itself.

This matters because bath bombs may contain fragrance oils that are temperature sensitive. While shrink tunnels typically heat the film rather than the product core, excessive dwell time can still warm the surface enough to influence scent volatility or soften decorative inclusions. A properly tuned tunnel minimizes thermal stress while delivering a smooth, uniform shrink.

Film Choice and Its Relationship to Bath Bomb Protection

Film selection directly affects how well the pack protects against moisture and scuffing, and how the product looks on a shelf. Film also influences sealing stability, clarity, and whether the pack feels“crinkly”or“soft” in hand—small details that shape the consumer experience.

The most common shrink films for cosmetics and personal care are polyolefin (POF) and polyethylene (PE). POF is widely used for retail presentation because it is clear, strong, and typically shrinks evenly, producing a neat appearance. PE is often used for heavier multi-packs or when greater thickness is needed for puncture resistance. Some bath bomb packs also include perforations or micro-holes for specific needs, but this must be considered carefully: excessive venting can undermine moisture protection, especially in humid storage.

Common Bath Bomb Pack Styles and When They Work Best

Bath bombs are sold in multiple formats: single units, gift sets, and assorted multi-packs. Shrink wrapping can serve each style, but the handling strategy differs. Single bombs need gentle infeed control and accurate spacing; multi-packs require stable collation so that products don’t collide during shrinking. Gift sets sometimes combine a tray or a paperboard base with shrink film, creating both structure and visibility. When products include decorative toppings (flowers, glitter, embeds), extra clearance or supportive inserts may be needed so the film does not press fragile elements too tightly during shrinking.

Reference Table: Packaging Decisions That Matter Most for Bath Bomb Shrink Wrapping

Packaging Factor | Why It Matters for Bath Bombs | Typical Challenge | Practical Consideration |

Moisture Barrier | Prevents premature fizzing and softening | Humidity absorption during storage and shipping | Choose film with stable sealing and limit unnecessary venting |

Surface Protection | Reduces scuffing, dusting, and color transfer | Chipping from vibration or contact | Tight, even shrink improves abrasion resistance |

Heat Exposure Control | Protects fragrance and decorative surface | Overheating can cause wrinkles or scent changes | Balance tunnel temperature, airflow, and dwell time |

Pack Appearance | Impacts perceived freshness and quality | Wrinkles, loose film, uneven corners | Film type and consistent shrinking parameters are critical |

Handling Stability | Prevents damage before sealing and shrinking | Rolling products or collisions on infeed | Use controlled spacing and stable product transfer design |

Storage, Logistics, and Shelf-Life Considerations

Even after packaging, bath bombs remain sensitive to the storage environment. Shrink wrapping reduces direct exposure but does not make the product immune to extreme humidity. Warehouses and shipping containers can create condensation events, especially when moving between climates. In those cases, shrink film helps but may be complemented by outer cartons, desiccant strategies at the case level, and controlled storage practices.

Shrink packaging also improves shipping efficiency because the wrapped surface resists abrasion and prevents bath bomb dust from spreading across cartons. For e-commerce, shrink wrapping can be used as an inner protective layer before adding cushioning material, reducing customer complaints caused by powdering or broken edges.

Quality Control: What to Watch During Production

Bath bomb shrink wrapping quality is typically evaluated through a combination of visual inspection and simple functional checks. A good shrink pack should be tight without warping the product, with seals that remain intact under normal handling. Common issues include end-seal burn-through, back-seal contamination from dust, and uneven shrink caused by airflow imbalance in the tunnel. Many of these issues are not “film problems” alone—they often reflect upstream realities such as powder residue, unstable infeed spacing, or inconsistent product dimensions.

Because bath bombs vary in shape more than molded plastics or standard boxes, consistent product sizing and curing time before packaging can significantly improve shrink results. Packaging performance is therefore tied to upstream manufacturing discipline, not only the machine settings.

Conclusion

Bath bomb packaging is a technically sensitive task because the product is both moisture-reactive and mechanically fragile. A heat shrink wrapping machine combined with a heat shrink tunnel provides a practical way to protect bath bombs from scuffing, reduce surface contamination, and improve durability through distribution while keeping product visibility high. The effectiveness of this approach depends on thoughtful control of film choice, infeed handling, sealing cleanliness, and tunnel parameters—each of which directly influences product appearance, scent stability, and customer experience.

When bath bomb packaging is treated as a material-science and handling problem rather than a simple wrapping step, shrink systems become a reliable method for maintaining both function and presentation across retail and e-commerce channels.

Get the latest price? We'll respond as soon as possible(within 12 hours)