Beef Jerky Packaging: Precision, Freshness, and Efficiency in Modern Food Processing

Introduction

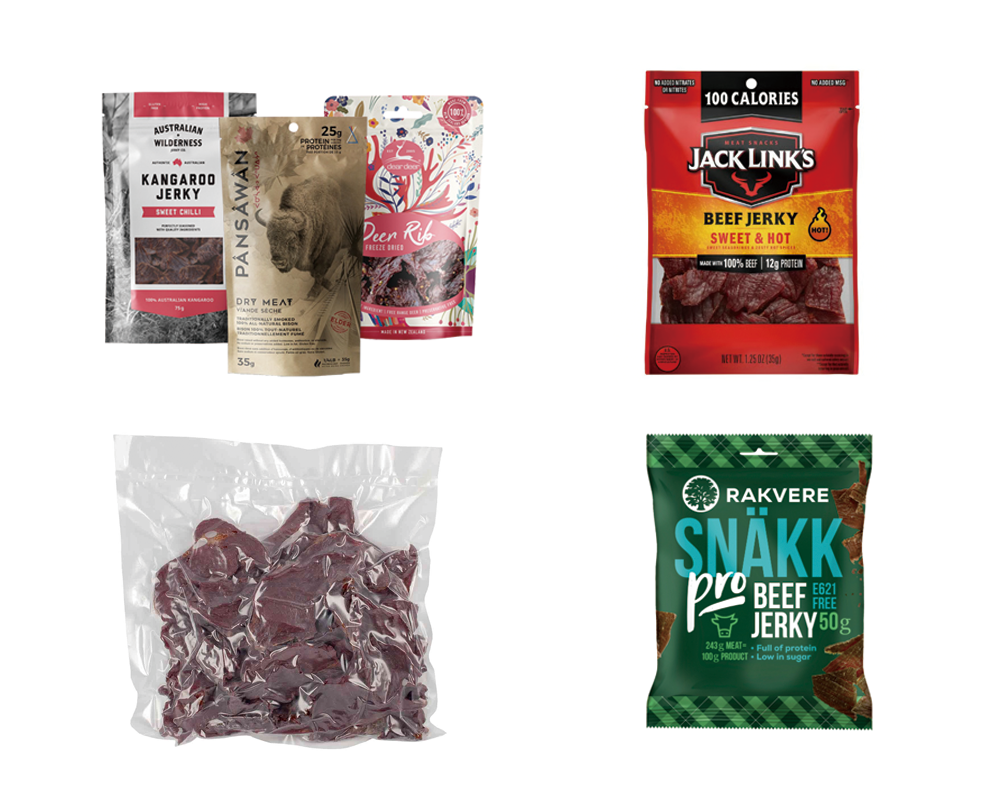

Beef jerky, a high-protein snack loved worldwide for its rich flavor and long shelf life, requires meticulous packaging to preserve its freshness, aroma, and nutritional value. As global demand for convenient, ready-to-eat protein snacks continues to grow, packaging has evolved from a simple protective layer into an essential part of product quality assurance and brand identity. This article explores the science and technology behind modern beef jerky packaging, focusing on the integration of automated pouch systems in industrial production and how they ensure quality, safety, and efficiency.

Understanding the Nature of Beef Jerky

Beef jerky is produced through marination, seasoning, and drying processes that remove most of the moisture from the meat, creating a shelf-stable product with concentrated flavor and long-lasting texture. However, its low moisture content makes it sensitive to oxygen, light, and humidity—all of which can lead to oxidation, flavor loss, or microbial contamination if not properly managed. Effective packaging must therefore combine strong barrier protection with aesthetic presentation and consumer convenience.

Flexible pouches, vacuum-sealed bags, and resealable zipper packs have become the preferred packaging options for jerky, offering durability, ease of use, and extended shelf life. In addition, packaging design influences consumer perception—modern, compact pouches with attractive graphics reinforce freshness and brand reliability.

Common Packaging Types for Beef Jerky

Packaging Type | Material Composition | Advantages | Typical Applications |

Flat Pouches | Multi-layer films (PET/PE, BOPP/CPP) with high barrier properties | Cost-effective, supports high-speed packaging | Small retail packs, samples |

Stand-Up Pouches | PET/AL/PE multilayer films | Excellent shelf display, strong protection | Premium retail jerky packs |

Vacuum Bags | High-barrier nylon/PE | Maximized shelf life, moisture and oxygen control | Bulk or export packaging |

Zipper Pouches | Resealable multilayer film | Convenient for resealing, reusable | Family-size or snack packs |

The Role of Automation in Jerky Packaging

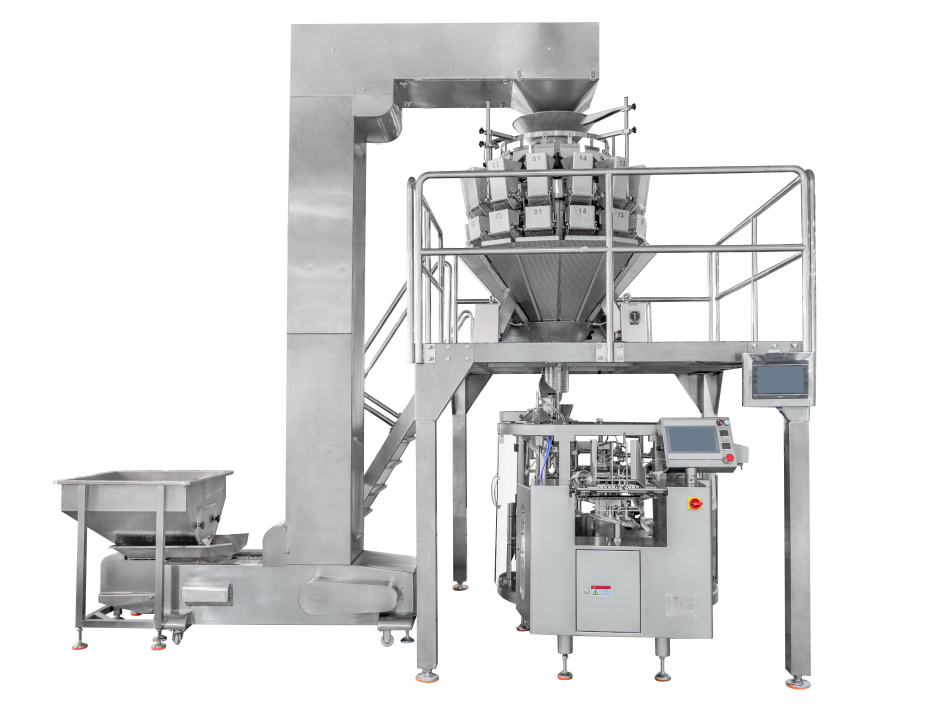

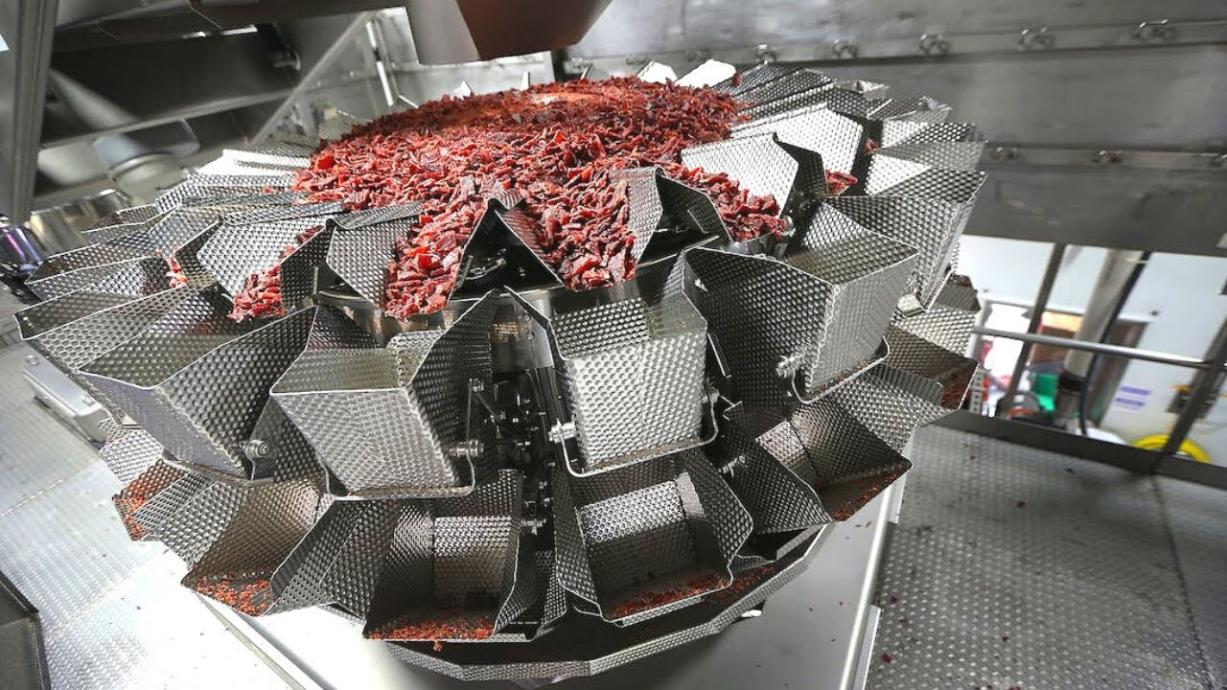

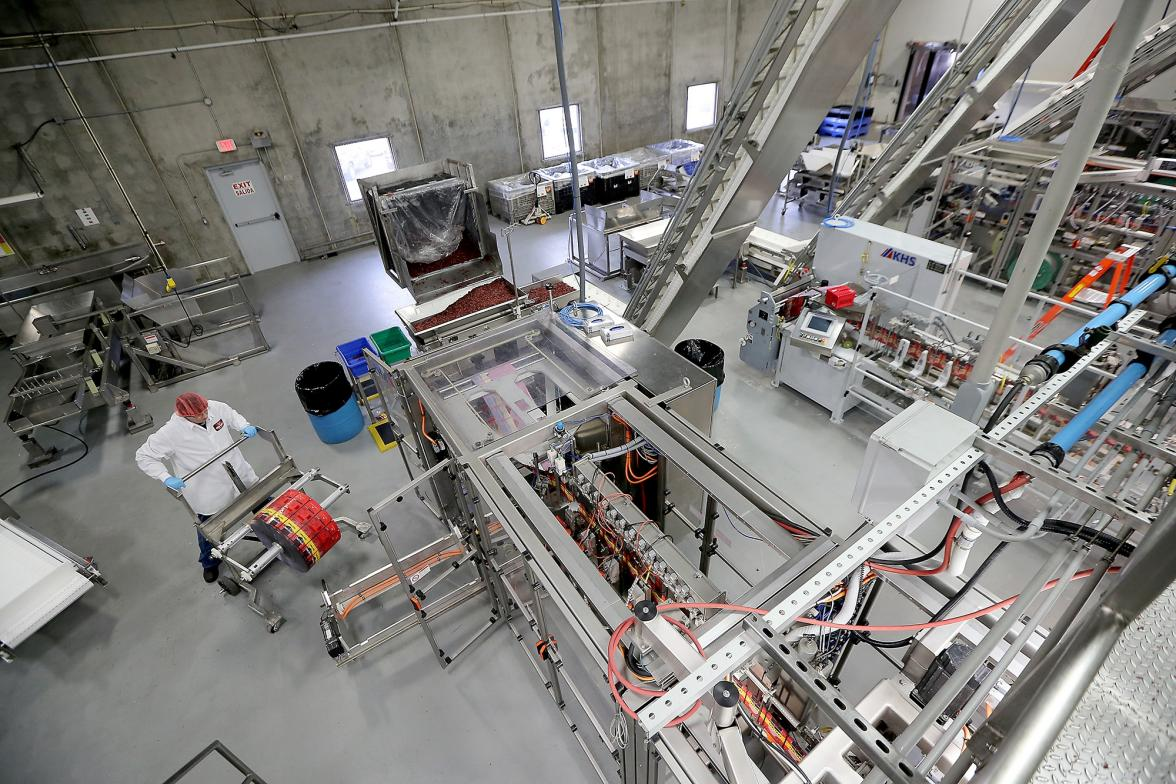

Modern jerky packaging lines rely heavily on automation to achieve consistency, speed, and hygiene. In a typical production setup, dried jerky pieces are first lifted via a Z-type elevator that gently conveys them from the processing area to the multihead weigher, minimizing product breakage. The weigher, equipped with multiple precision load cells, calculates the ideal combination of jerky portions to meet exact target weights, ensuring uniformity across all pouches.

Once the weighing is complete, the jerky is transferred to a pre-made pouch packaging machine, which automatically opens, fills, and seals the pouches. These systems handle a wide range of bag types — from flat to stand-up and resealable zipper styles — and can easily switch between packaging formats depending on production needs. The seamless coordination among these machines creates a continuous, high-efficiency process that reduces manual handling, enhances product hygiene, and maintains precise weight control.

By integrating automated feeding, weighing, and packaging in one synchronized flow, manufacturers can achieve higher throughput and reduced product loss while ensuring that every pouch looks and performs consistently.

Ensuring Freshness and Shelf Life

Beef jerky’s quality depends heavily on its packaging environment. Modern jerky packs are typically constructed from multi-layer barrier films combining PET, aluminum foil, and PE layers that block oxygen and moisture. Many producers include desiccant sachets or oxygen absorbers to further prevent spoilage.

In hot or humid regions, the use of high-barrier laminates and precision sealing technology becomes even more critical. A perfectly sealed pouch prevents the exchange of air and moisture, ensuring that the jerky retains its intended flavor and texture for months. Maintaining packaging integrity during transportation and storage is therefore a key indicator of overall product quality.

Hygiene and Food Safety Standards

Automated jerky packaging systems are designed to comply with international food safety standards such as HACCP and ISO 22000. Stainless-steel frames, food-grade contact surfaces, and easy-clean components minimize contamination risks and simplify maintenance. Since jerky is a ready-to-eat product, maintaining a clean environment throughout packaging is essential.

The reduced need for manual intervention also limits potential microbial transfer. In addition, advanced sensors and PLC control systems continuously monitor sealing temperature, film tension, and fill accuracy — ensuring that every package meets both safety and aesthetic standards before reaching consumers.

Case Study: Efficient Packaging Line for Premium Beef Jerky

A mid-sized jerky manufacturer in Southeast Asia recently implemented a fully automated packaging line combining a pre-made pouch machine, 14-head weigher, and Z-type elevator. Prior to automation, the company relied on manual filling and sealing, which limited output to around 10 packs per minute.

After installing the new integrated system, production speed increased to over 40 packs per minute while maintaining a weight accuracy within ±0.2 grams. The automated process reduced film waste by 12% and improved sealing consistency, resulting in better shelf life and reduced customer complaints. The system’s flexibility also allowed the company to switch between 50 g and 200 g retail pouch formats seamlessly.

This case illustrates how automation enhances efficiency and product consistency without compromising quality — a critical advantage for snack food producers competing in export markets.

Sustainability and Market Trends

Sustainability continues to influence the jerky packaging landscape. Brands are gradually adopting recyclable laminates and biodegradable films as alternatives to aluminum-based materials. Lightweight packaging structures reduce carbon emissions during transportation, while digital printing technologies allow smaller, customized runs that cater to niche markets or promotional campaigns.

Consumers are also increasingly aware of the environmental impact of their purchases, encouraging manufacturers to pursue eco-friendly packaging innovations that balance performance and responsibility.

Conclusion

Beef jerky packaging sits at the intersection of technology, food science, and consumer demand. The combination of pre-made pouch packaging machines, multihead weighers, and Z-type elevators has transformed the way jerky products are handled, improving accuracy, speed, and hygiene. Through careful material selection, precise automation, and attention to sustainability, modern packaging ensures that every pouch of jerky reaches consumers as fresh, flavorful, and safe as when it left the factory.

As the global snack market continues to expand, the role of intelligent, efficient packaging systems will only grow — shaping the future of how we preserve and enjoy one of the world’s most iconic protein snacks.

Get the latest price? We'll respond as soon as possible(within 12 hours)