The Science of Tea Packaging: Preserving Flavor, Aroma, and Quality

Introduction

Tea is one of the most consumed beverages in the world, with a history spanning thousands of years. From loose-leaf green tea to finely ground matcha, packaging plays a crucial role in maintaining freshness, preventing contamination, and extending shelf life. Modern tea packaging solutions not only focus on protection but also on sustainability, convenience, and efficiency.

The Journey of Tea: From Leaf to Cup

Before diving into packaging technologies, it is essential to understand the general process of tea production. Tea leaves typically undergo the following steps:

1. Plucking–Tender leaves are handpicked or machine-harvested.

2. Withering–Leaves are spread out to reduce moisture content.

3. Rolling–The leaves are rolled to break cell walls and release essential oils.

4. Oxidation/Fermentation–Depending on tea type (black, green, oolong), leaves may be oxidized to develop flavor and color.

5. Drying–Moisture is removed to stabilize the tea for storage.

6. Sorting and Grading–Leaves are categorized by size and quality.

Once processed, tea must be carefully packaged to protect these delicate qualities from oxygen, moisture, and light exposure.

Why Packaging Matters for Tea

Tea leaves are highly sensitive to external factors such as oxygen, moisture, light, and odors. Even minimal exposure can alter the flavor profile, reduce aroma intensity, and shorten storage stability. Proper packaging ensures that teas—whether black, green, oolong, herbal, or blended—retain their essential oils and antioxidant compounds until they reach the consumer’s cup.

Common Types of Tea Packaging

Different forms of tea require specialized packaging approaches. Below is a comparative table of the most common formats:

Packaging Type | Characteristics | Advantages | Limitations |

Tea Bags | Porous filter paper or biodegradable mesh | Convenient, portion-controlled | Limited aroma retention |

Loose-Leaf Pouches | Flexible laminated pouches with resealable zippers | Good aroma retention, lightweight, customizable | Requires scoop or utensil |

Tins and Caddies | Metal containers, often with inner sealing lids | Excellent protection from light & oxygen | Higher cost, heavier |

Paper Boxes | Simple folded cartons, sometimes with inner lining | Eco-friendly, recyclable | Limited barrier properties |

Sachets or Stick Packs | Individually sealed small units | Hygienic, on-the-go use | More packaging material per serving |

Modern Tea Packaging Innovations

In recent years, technological improvements have revolutionized tea packaging. Flexible pouches with resealable zippers and gas-barrier films are now widely adopted. These pouches are lightweight, customizable in design, and suitable for both premium loose-leaf teas and commercial blends. Tins and caddies remain popular in high-end markets, but flexible solutions dominate because of their cost-efficiency and adaptability.

Another major innovation is modified atmosphere packaging (MAP). By flushing pouches with nitrogen or inert gases, oxygen exposure is minimized, thereby slowing oxidation and preserving the delicate flavors of tea for extended periods.

Automation in Tea Packaging

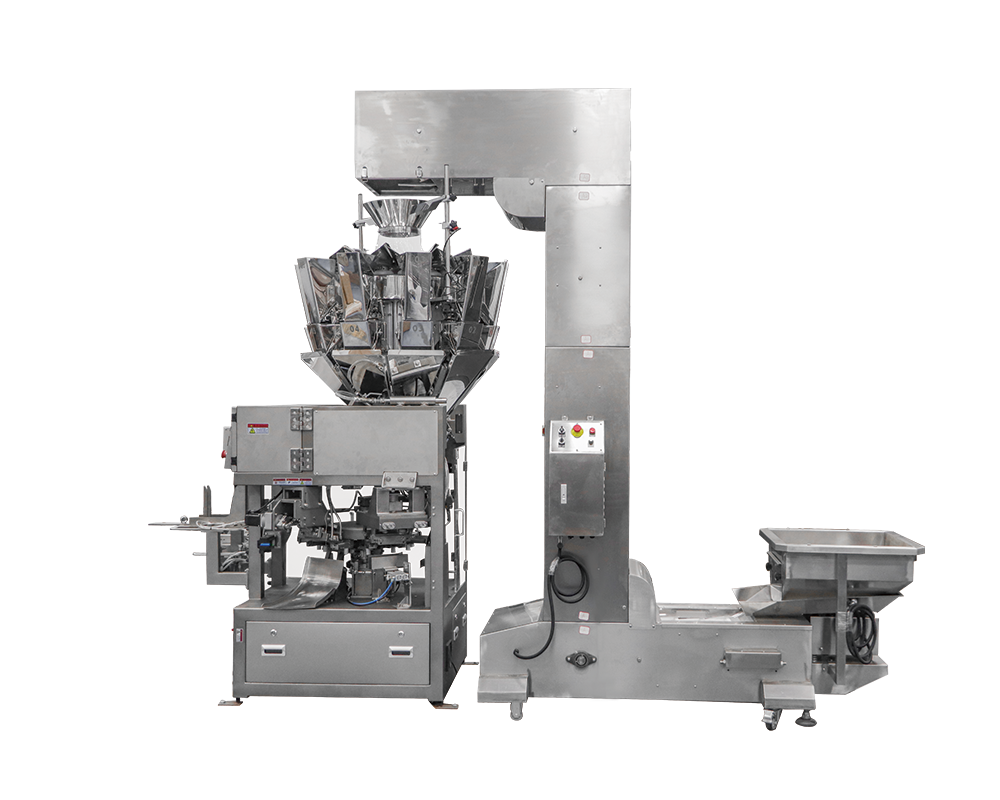

Automation ensures consistency and efficiency, especially in large-scale production. Pre-made pouch packaging machines combined with 10-head weighers are widely used for loose-leaf tea and granulated blends. The weighers provide high accuracy when dispensing fragile tea leaves, minimizing breakage while maintaining precise filling.

Furthermore, when equipped with a gas-flushing system, these machines significantly enhance shelf life by creating a protective environment inside each pouch. This is particularly important for premium teas where aroma preservation is a priority. Pre-made pouch machines are flexible, handling different pouch styles—stand-up, flat-bottom, or zipper resealable—making them ideal for both retail and wholesale markets.

Sustainability and Consumer Expectations

Today’s consumers demand both freshness and eco-conscious solutions. Many tea brands are shifting toward recyclable films, biodegradable mesh for tea bags, and reusable tins. Packaging machinery is adapting to these requirements by supporting compostable films and recyclable laminates without compromising sealing integrity.

Conclusion

Tea packaging is a delicate balance between tradition and technology. While tins and tea bags remain relevant, flexible pouch solutions with automated filling systems represent the future of tea packaging. With the integration of pre-made pouch machines, multihead weighers, and nitrogen-flushing technology, producers can achieve longer shelf life, better flavor preservation, and more sustainable operations—ensuring that every cup of tea delivers the authentic taste consumers expect.

Get the latest price? We'll respond as soon as possible(within 12 hours)