A Comprehensive Guide to Coffee Packaging: Structure, Materials, and Automation

Introduction

Coffee packaging plays a critical role in maintaining the quality of the product from roaster to consumer. It protects against moisture, oxygen, light, and physical damage, while also serving informational and logistical functions such as labeling, traceability, and storage compatibility.

Depending on the form of the coffee—whole bean, ground, instant,or single-serve—the packaging solution must meet specific requirements in terms of barrier properties, shelf life, and handling.

Common Coffee Packaging Types

There are several widely used packaging formats in the coffee industry. Each format serves specific functional and aesthetic purposes:

Packaging Type | Advantages | Best For |

Vertical Form Fill Seal (VFFS) | High-speed operation, cost-effective for large volumes, compact machine footprint. | Ground coffee, instant coffee in stick packs or pillow bags. |

Pre-made Pouch Packaging | Premium appearance, good for retail shelves, flexible for various pouch types. | Whole bean or ground coffee in stand-up pouches, gusseted bags, zipper bags. |

Drip Bag Coffee Packaging | Specialty niche packaging for single-serve convenience, enhances brand image. | Single-serve pour-over coffee, specialty brews. |

Essential Packaging Materials for Coffee

Coffee is sensitive to oxygen, moisture, and UV light. Therefore, most coffee packages use multilayer films with high-barrier properties. Common material structures include:

PET/AL/PE (Polyester/Aluminum/Polyethylene): Provides excellent oxygen and moisture barrier; suitable for long-term storage.

Kraft paper laminated with PE: Combines a natural appearance with basic protection; often used for organic or artisan brands.

PLA-based compostable films: Used in environmentally conscious packaging; performance varies depending on formulation.

Material Selection Considerations

Barrier strength (Oxygen Transmission Rate, Moisture Vapor Transmission Rate)

Heat seal compatibility with the selected packaging machine

Printability for branding or labeling

End-of-life treatment (recyclability, compostability, etc.)

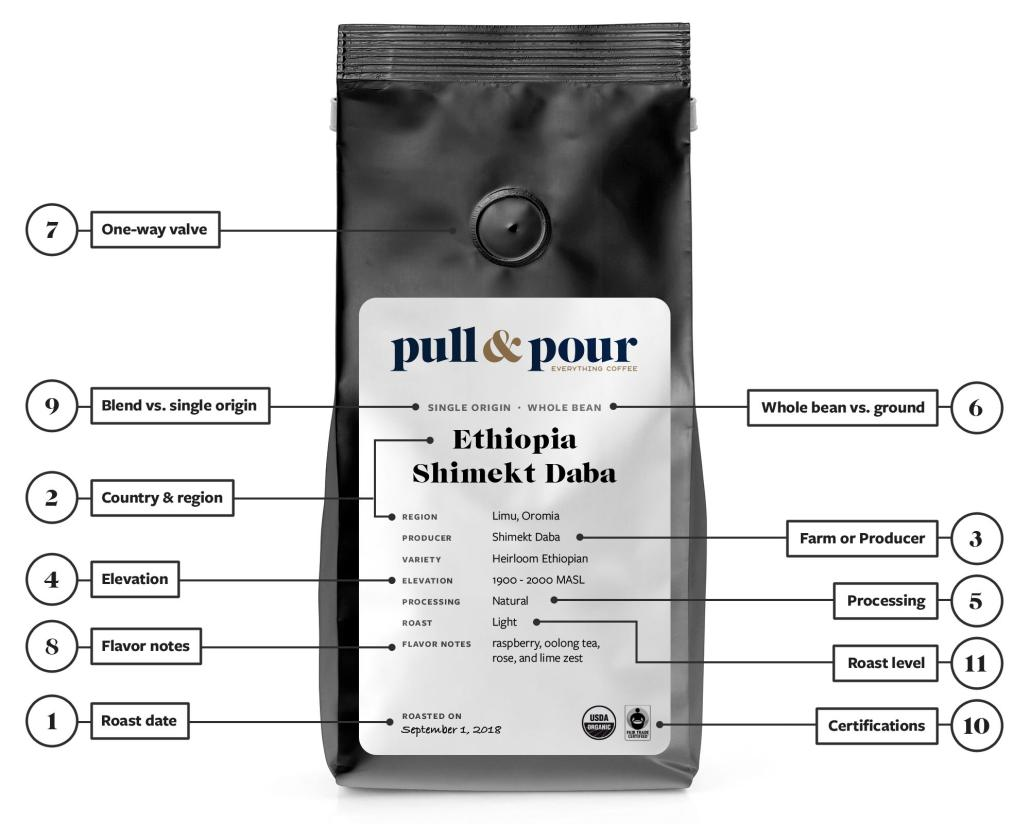

Common Features in Coffee Packaging

Modern coffee packages often incorporate the following functional components:

Degassing valve: Allows CO₂to escape from freshly roasted beans while preventing oxygen from entering.

Zipper seals or resealable closures: Extend usability for the consumer after opening.

Nitrogen flushing: Used during packaging to displace oxygen, preserving freshness.

Tear notches and easy-open designs: Improve consumer convenience.

These features affect packaging material choices and machine configurations.

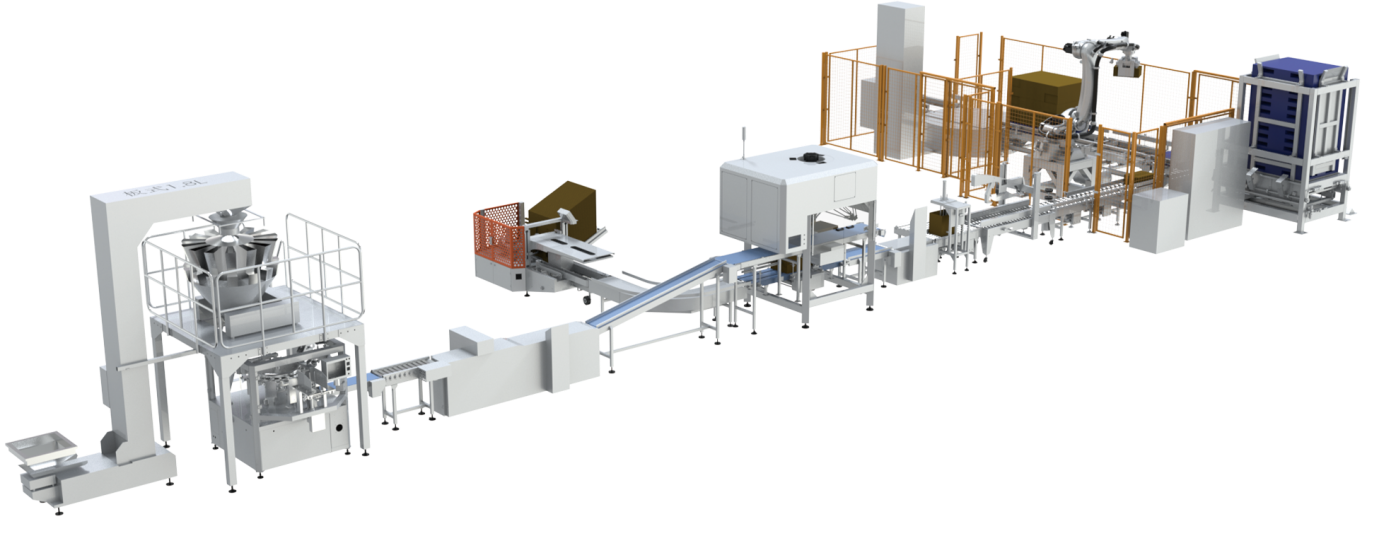

Overview of Coffee Packaging Equipment

Coffee packaging can be done manually, semi-automatically, or with full automation. For medium to large production volumes, automated packaging systems offer greater consistency and efficiency. The following machine types are commonly used:

1. Vertical Form Fill Seal Machine (VFFS)

Forms a bag from film, fills it with coffee, and seals it.

Compatible with pillow bags, flat-bottom bags, and gusseted pouches.

Can be equipped with:

Auger filler for ground coffee (for accurate dosing of powders)

Multihead weigher for whole beans

Nitrogen gas flushing system

2. Premade Pouch Packaging Machine

Works with ready-made bags (e.g., stand-up pouches).

Fills and seals preformed pouches on a rotating platform.

Suitable for specialty packaging that requires zippers, valves, or complex shapes.

3. Drip Coffee Bag Packaging Machine

Specialized system that assembles, fills, and seals filter-style drip bags.

Often includes inner and outer bagging, date coding, and tear notches.

Each system can be integrated with conveyors, labelers, or checkweighers for a complete packaging line.

Preservation Techniques: Extending Shelf Life

Roasted coffee continues to release carbon dioxide for several days after roasting. Exposure to air and moisture leads to oxidation and staleness. Common preservation methods include:

Vacuum sealing: Removes air from the bag.

Nitrogen flushing: Replaces air with inert nitrogen gas to slow oxidation.

Degassing valves: Allow CO₂to exit while preventing oxygen from entering.

These techniques help maintain aroma and flavor, especially important for export or long storage periods.

Labeling and Traceability in Coffee Packaging

Labeling serves regulatory and marketing purposes. A standard coffee package label may include:

Product name and weight

Roast date and “best by” date

Origin or blend description

Brewing instructions

Certification marks (e.g., organic, fair trade)

Lot number or QR code for traceability

Automated labeling systems and inkjet printers can be integrated with packaging machines to ensure accurate, real-time coding.

Environmental Considerations

The coffee industry is increasingly adopting sustainable practices in packaging. Key developments include:

Biodegradable and compostable films for single-use packs

Mono-material packaging that simplifies recycling

Reduced material thickness to lower overall plastic usage

Packaging reuse systems in subscription or refill models

These approaches often require fine-tuning of sealing temperature, machine timing, and handling to avoid material failure or leakage.

Conclusion

Effective coffee packaging involves multiple technical elements—from barrier material selection and functional features to compatibility with machinery and preservation requirements. A well-designed packaging system protects product quality, meets logistical requirements, and supports regulatory compliance.

Understanding these core concepts is essential for coffee producers, equipment integrators, and brand developers aiming to optimize packaging efficiency and consistency.

Get the latest price? We'll respond as soon as possible(within 12 hours)