Understanding Compact Four-Station Premade Pouch Packaging with 10-Head Weighing Integration

Introduction

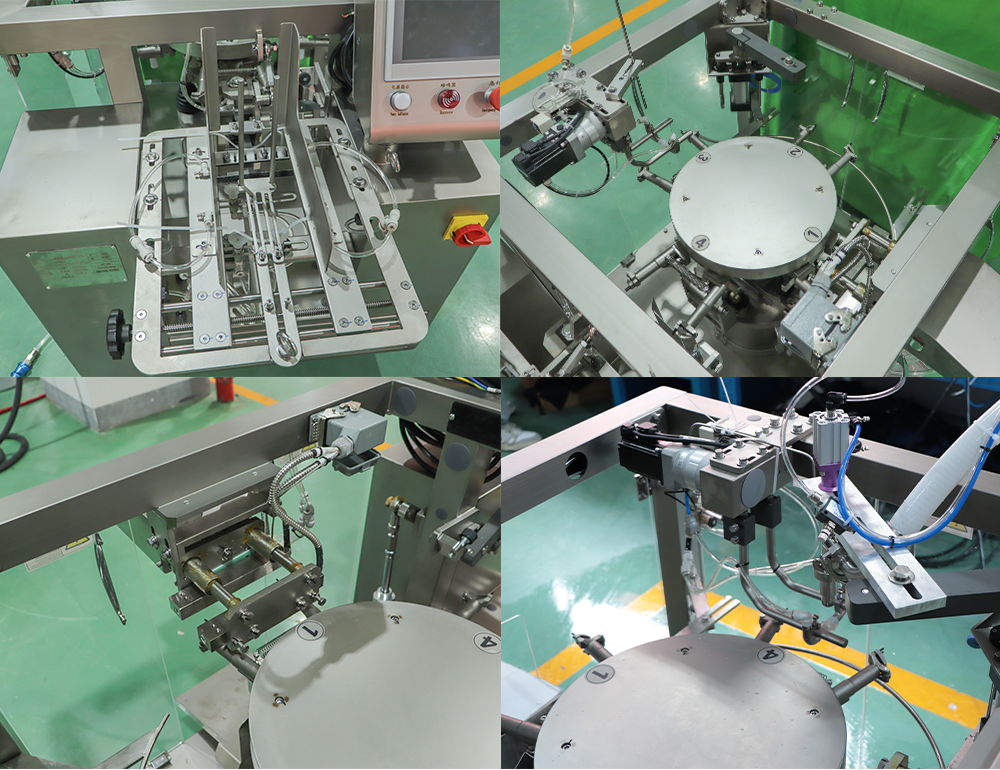

In modern packaging environments, especially those operating within compact facilities or early-stage production floors, a four-station premade pouch machine integrated with a 10-head weighing system offers an approach defined not by speed escalation, but by spatial discipline, accuracy, and stable repeatability. Unlike rotary systems with eight or ten work positions, the four-station layout organizes the pouch journey into a shorter, more controlled cycle, where pouch pick-up, opening, filling, and sealing occur with minimal mechanical transfer distance. This reduction in motion points results in fewer timing conflicts, lower cumulative vibration, and a sealing rhythm that is easier to stabilize across different laminate films and pouch constructions.

Machine Structure as the Core Logic

The ten-head weighing component complements this restrained pacing by focusing on predictable dosing accuracy instead of maximizing volume flow. The weighing heads allow product distribution to settle before calculation, keeping combination deviations narrow across small or moderately dense granular products. When integrated vertically above the pouch line, gravity does most of the work without forcing the product through augers, wipers, or high-friction funnels. As a result, powders, seeds, snack cubes, granulated herb mixes, or dehydrated pieces fall with consistency and without breakage, dust recoil, or static-cling accumulation that can challenge sealing integrity.

What differentiates the four-station layout is not merely its size, but its reduced operational burden. Operators do not need extended catwalk access, multiple rotary tuning points, or complex synchronization resets. Clamp width adjustments, pouch gripper recalibration, and film opening vacuum strength can be modified within a short mechanical radius. The machine’s compact geometry is particularly advantageous in environments where a single line must coexist with weighing calibration desks, allergen segregation tables, manual inspection zones, or secondary labeling equipment. This spatial economy ensures that product flow feels like a controlled loop rather than a sprawling plant layout.

Because there are fewer operational steps, stoppage visualization becomes more direct. When sealing pressure, gusset opening, pouch zipper preheat, or weigh timing need tuning, the cause-and-effect link remains visible rather than lost across too many carousel stations. Production managers often report that defect tracing and line clearing occur faster precisely because the machine does less, but does it with higher clarity.

Pouch Format Flexibility with Minimal Mechanical Burden

The flexibility of the four-station concept is not derived from over-engineering but from its restrained simplicity. Moving from Doy-zip formats to flat-bottom coffee-style formats or smaller sample pouches generally requires only clamp width correction, fill height recalculation, and sealing dwell adjustment rather than fixture replacement. This lean setup culture benefits facilities where small-batch SKU runs, seasonal limited editions, nutraceutical trials, and diversified snack assortments rotate frequently.

Brands working with organic herbal blends, rehydrated wellness cubes, botanical teas, energy bites, premium nuts, or dehydrated pet treats often choose this format not because they are scaling down, but because they are scaling with intentional variation. The packaging machine thus becomes an adaptive tool rather than a throughput hostage.

Weighing Stability in Controlled-Speed Packaging

The ten-head weighing system enhances the four-station philosophy by delivering quantitative precision without forcing the product into a high-acceleration drop cycle. When velocity is kept moderate, product landing zones do not shift, seal contamination remains rare, and pouch distortion reduces significantly. The reduced turbulence inside the pouch also improves oxygen-barrier consistency and laminate integrity. Cost control emerges organically, as overfill reduction is not achieved with aggressive rejection algorithms but with quieter, more consistent dosing combinations.

This stable operating rhythm is especially helpful in food categories that present irregular geometry—cube jerky bites, freeze-dried fruit clusters, nut blends, brittle snacks, brittle sugar grain shapes—where hectic weighing speeds can compromise particle integrity or pouch presentation.

Application for Small-Footprint, SKU-Dense Production Models

Micro-batch producers, specialty nutrition developers, farmers’ market processors, and early-stage consumer packaged goods brands frequently describe their environments as “space-alive rather than space-abundant.” In these settings, every square meter must serve multiple purposes: batching, allergen isolation, label application, sealing verification, pouch conditioning, and case packing. The compact four-station layout integrates not as a dominant anchor, but as a cooperative component within the room’s architecture.

Rather than chasing maximum bags per minute, these producers prioritize label traceability, seal auditability, pouch upright display requirements, small weight variances, and customized ingredient rotation. The machine, by virtue of its spatial reserve, becomes compatible with that workflow rather than defining it.

Reference Table: Interaction Between Weighing Logic and Pouch Types

Pouch Type | Mechanical Note | Behavior with 10-Head Weighing | Best Fit Context |

Doy-Zip | Resealable, rigid stance | Controlled landing, minimal bounce | Snacks, nut mixes, pet treats |

Flat-Bottom | Broad sealing surface | Stable fill plane, clean top seal | Specialty blends, gift packs |

Side-Gusset | Flexible profile, depth variations | Requires clamp precision but maintains drop accuracy | Granules, jerky cubes, dried fruit |

Small Sample Pillow | Tight seal zone | Low-mass dosing prevents seal contamination | Sampling programs, limited trial runs |

Conclusion

The four-station + ten-head weighing configuration is best understood as an engineering stance rather than a market alternative. It favors clarity of motion, controlled dosing rhythm, and spatial intelligence over maximal output. In manufacturing environments where packaging must accommodate variety, changeover, and incremental quality audits more than relentless speed targets, this system provides a technological vocabulary that feels proportionate to the work.

Speed, in this context, is no longer the competitive metric. Instead, the value lies in the quiet predictability of pouch behavior, the consistency of sealing temperature and dwell, the repeatability of weight accuracy, and the physical humility of a machine that integrates into production rather than demanding space dominance.

Get the latest price? We'll respond as soon as possible(within 12 hours)