Sugar Packaging: Innovations, Materials, and the Role of Pre-Made Bag Machines

Introduction

Sugar, as one of the most widely consumed food ingredients globally, requires packaging solutions that ensure product safety, maintain freshness, and offer convenience in handling and storage. Over the years, sugar packaging has evolved from traditional paper sacks and polyethylene bags to advanced packaging types such as spout pouches. These modern formats not only enhance shelf appeal but also meet consumer demands for portability and resealability.

The Importance of Sugar Packaging in Modern Markets

Packaging plays a dual role in sugar distribution: protecting the product from external contaminants like moisture and dust while also serving as a branding and communication tool. In large-scale supply chains, packaging integrity ensures sugar maintains its free-flowing granulated texture and avoids clumping. Furthermore, with increasing retail competition, visually appealing packaging also strengthens consumer trust and preference.

Spout Pouches for Sugar Packaging

One of the more recent advancements in sugar packaging is the use of spout pouches, a format that has gained popularity in both domestic and export markets. Spout pouches are lightweight, easy to reseal, and allow controlled dispensing, which makes them highly practical for consumers who use sugar in daily cooking or beverage preparation. Unlike traditional bags that require cutting and resealing, spout pouches reduce waste and improve convenience. Additionally, they are ideal for e-commerce shipping, as their durability prevents leakage during transport.

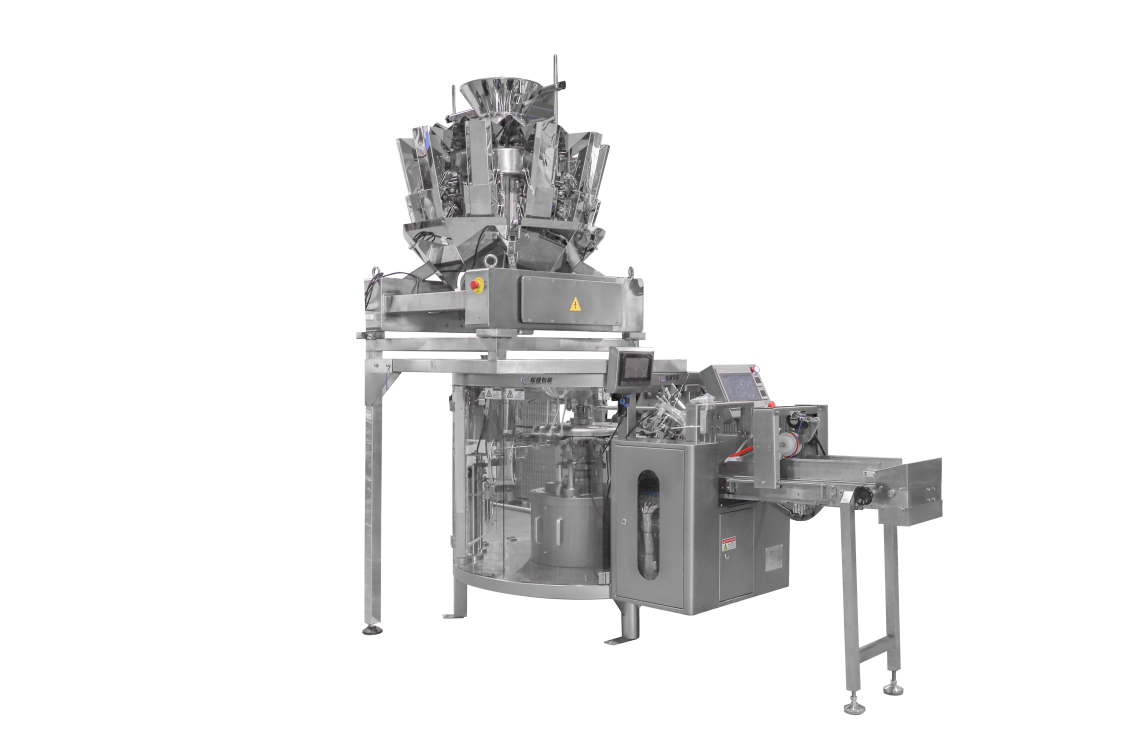

Packaging Machine Integration: Pre-Made Bag System

For manufacturers, the adoption of automation is central to efficiency and quality assurance. A pre-made bag packaging machine, integrated with a ten-head weigher and a horizontal bag feeder for spout pouch storage and feeding, provides a reliable solution for sugar packaging. The ten-head weigher ensures precise dosing of sugar, reducing giveaway and maintaining consistency. The horizontal bag feeder automates the storage and insertion of spout pouches into the packaging line, enabling smooth continuous operation. Once the pouches are filled, the pre-made bag machine seals them securely, producing uniform, shelf-ready packaging. This integration significantly reduces labor requirements, ensures hygienic processing, and boosts production speed to meet growing market demand.

Ensuring Safety and Quality in Sugar Packaging

Sugar, though a dry product, is highly sensitive to moisture absorption. Even slight exposure can cause clumping, reducing usability. High-barrier materials such as laminated films with moisture-resistant properties are commonly used to address this challenge. Automated packaging systems further contribute to quality by minimizing direct human contact, thereby reducing contamination risks. For spout pouches in particular, robust sealing ensures the contents remain dry, extending shelf life and safeguarding product integrity throughout distribution.

Sustainability and Consumer Preferences

Modern consumers increasingly prioritize eco-friendly packaging solutions. In the sugar sector, this trend has encouraged the development of recyclable or partially biodegradable spout pouches. While plastic-based laminates remain standard due to their protective qualities, ongoing innovation aims to balance sustainability with functionality. Pre-made bag packaging machines are compatible with these new eco-materials, allowing manufacturers to transition smoothly toward greener solutions without compromising efficiency.

Packaging Materials for Sugar: A Comparative View

Packaging Material | Advantages | Limitations | Common Applications |

Paper Bags | Low cost, recyclable, easy to print | Poor moisture resistance | Bulk sugar in retail and wholesale |

Polyethylene Bags | Lightweight, flexible, good protection | Limited resealability | Granulated sugar packs for households |

Spout Pouches | Resealable, durable, convenient dispensing, strong for e-commerce | Higher production cost | Retail sugar packaging, export packaging |

Laminated Films | Excellent barrier properties, customizable | Less eco-friendly | Premium branded sugar packaging |

Future of Sugar Packaging

As global consumption of sugar continues to grow, packaging will play an increasingly critical role in differentiating brands, reducing waste, and improving supply chain efficiency. Spout pouches, paired with advanced packaging lines such as pre-made bag machines with precision weighers and automated feeders, represent a forward-looking solution. By combining functionality, safety, and consumer convenience, these packaging innovations will continue to shape the future of the sugar industry.

Get the latest price? We'll respond as soon as possible(within 12 hours)