A Comprehensive Guide to Fresh Vegetable Packaging

Introduction

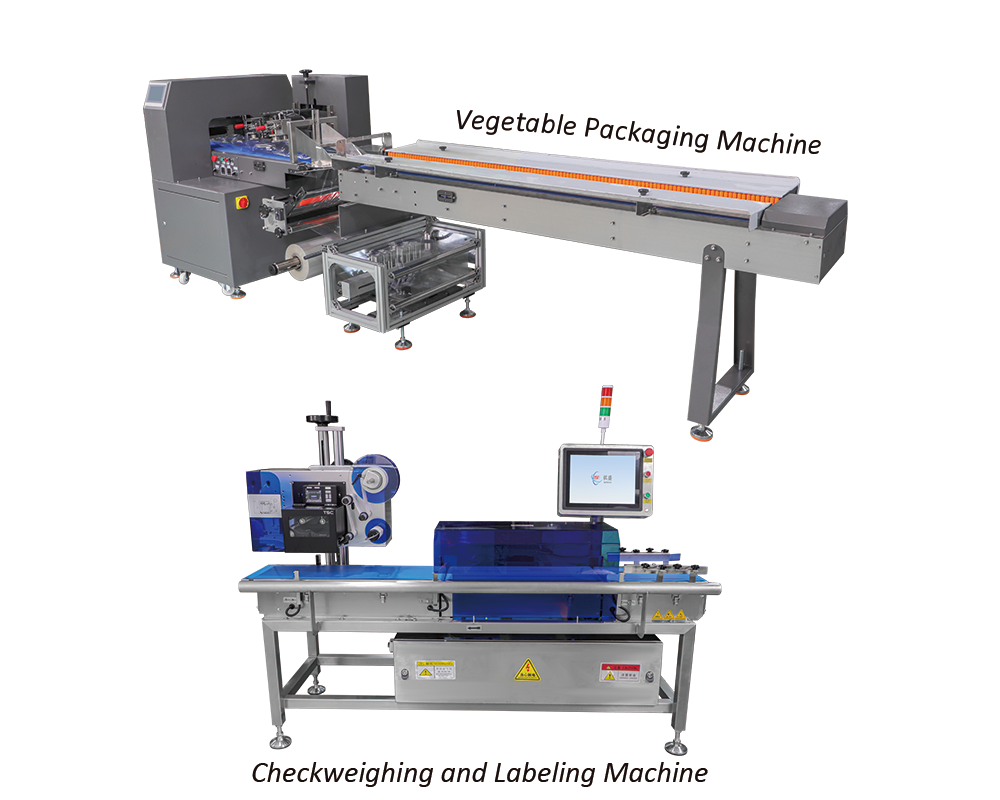

Fresh vegetables are among the most sensitive and perishable products in the food industry. From the moment they are harvested, they begin to lose moisture and nutrients, and their natural respiration continues, affecting texture, taste, and appearance. Without effective packaging, these changes accelerate, leading to reduced shelf life and increased waste. Packaging plays a much bigger role than simply containing the product — it directly influences freshness, safety, marketability, and sustainability. Today, many commercial vegetable packaging lines integrate horizontal flow wrapping machines, checkweighing labeling systems, and pneumatic hole punching devices to create a balanced solution that protects the product while meeting regulatory and operational demands.

The Challenges of Packaging Fresh Vegetables

Vegetables face unique post-harvest challenges. Because they continue to respire, they produce moisture and gases that, if trapped without proper ventilation, can lead to condensation, microbial growth, and rapid spoilage. On the other hand, excessive airflow can cause dehydration and wilting. Finding the right packaging balance is essential, as is ensuring the integrity of the pack during transportation and retail display. Regulations also play a major role, requiring accurate weight labeling, traceability information, and sometimes even country-of-origin details. At the same time, processors must maintain high throughput without compromising on gentle handling — a difficult task when working with produce of varying shapes, sizes, and fragility.

How Horizontal Flow Packaging Machines Support Freshness

The horizontal flow wrapping machine is a cornerstone of modern vegetable packaging lines. It wraps vegetables — whether loose items like cucumbers or carrots, or tray-packed leafy greens — in a continuous film that is heat-sealed and cut into uniform packs. This process creates a consistent seal that keeps out contaminants and helps retain moisture, while also producing a clean, professional appearance for retail. The versatility of flow wrapping allows it to handle multiple product types with quick changeovers, supporting seasonal variety. Because the film is applied under controlled tension and sealing temperatures, damage to delicate produce is minimized, and the final package has a uniform presentation that appeals to consumers.

Ensuring Accuracy with Checkweighing and Labeling

After wrapping, each package must be accurately weighed and labeled — not only to meet legal requirements, but also to maintain consumer trust. A checkweighing labeling system performs both functions in a single automated step. It verifies that each pack meets the declared net weight, rejects any that are under- or over-filled, and applies labels containing key product information such as variety name, weight, price, barcode, batch code, and best-before date. For exporters, additional data like certification marks or multilingual labels can be included. This stage improves traceability across the supply chain and helps retailers manage inventory efficiently, while also preventing costly product giveaways from overfilling.

Optimizing Shelf Life with Pneumatic Hole Punching

Because vegetables release gases after harvest, many types require ventilation in their packaging. A pneumatic hole punching device solves this by creating micro-perforations in the packaging film, either before or after sealing. These perforations allow a controlled exchange of oxygen and carbon dioxide, slowing down decay while preventing excess condensation. The pattern, size, and number of holes can be customized according to the respiration rate of each vegetable — for example, leafy greens may need more ventilation than root vegetables. This adjustment helps maintain color, crispness, and flavor, while extending shelf life during storage and display.

Designing a Complete Vegetable Packaging Line

An effective vegetable packaging line brings these elements together in a way that matches the product type, production volume, and market requirements. For example, thin film with optimized barrier properties can help control moisture levels, while machine settings can be fine-tuned to balance sealing strength with ease of opening for consumers. Integration between the horizontal flow wrapper, checkweigher, labeler, and hole puncher allows continuous operation with minimal downtime, reducing labor costs and improving efficiency. Data from the checkweigher can be logged for quality control, and adjustments to ventilation patterns can be made in real time if storage conditions change.

Packaging Material | Characteristics | Common Uses |

Polyethylene (PE) | Flexible, moisture-resistant, suitable for heat sealing. | Chips, frozen snacks, bakery products. |

Polypropylene (PP) | Good clarity, high tensile strength, suitable for snacks requiring visibility. | Nuts, candies, cookies. |

Biaxially Oriented Polypropylene (BOPP) | Excellent printability, moisture barrier, and shelf appeal. | Premium snacks, chips, confectionery. |

Polyethylene Terephthalate (PET) | High strength, good barrier properties, often combined with aluminum foil. | Long-shelf-life products, gourmet snacks. |

Paper | Eco-friendly, biodegradable, used for organic and artisanal snacks. | Organic snacks, eco-conscious brands. |

Compostable Films | Environmentally friendly, breaks down under composting conditions. | Sustainable brands, organic products. |

Sustainability in Vegetable Packaging

Sustainability is increasingly shaping packaging decisions. Many processors are moving toward recyclable polyethylene films or compostable plant-based alternatives. Reducing material thickness without compromising strength is another approach, as is optimizing machine operations to minimize film waste. Labels are also evolving, with water-based inks and biodegradable adhesives becoming more common. While the primary goal remains freshness and safety, sustainable practices can reduce environmental impact and enhance brand reputation in an eco-conscious marketplace.

Conclusion

Fresh vegetable packaging is both a science and a logistical challenge. By combining horizontal flow wrapping, checkweighing labeling, and pneumatic hole punching, producers can deliver products that maintain their natural appearance and taste, comply with strict labeling laws, and withstand the demands of modern distribution. When well-designed, a packaging line becomes more than just an operational necessity — it becomes a competitive advantage that supports product quality, reduces waste, and meets growing consumer expectations for freshness, transparency, and sustainability.

Get the latest price? We'll respond as soon as possible(within 12 hours)