Horizontal Spoon Packaging Machine: Precision Feeding and Efficient Packing with Vibratory Bowl & Horizontal Flow Wrapper

Introduction

In the baby product and dairy accessory industries, packaging small plastic tools like milk powder scoops requires precision, speed, and hygiene. Traditional manual packaging methods are time-consuming and inconsistent. To address these challenges, the combination of a vibratory feeding system and horizontal flow wrapping machine presents an ideal solution for the automated, high-speed packaging of individual milk powder scoops. This article introduces the components, working principle, and advantages of the milk powder scoop horizontal packaging machine, helping manufacturers ensure consistent product quality and streamlined production.

Key Features

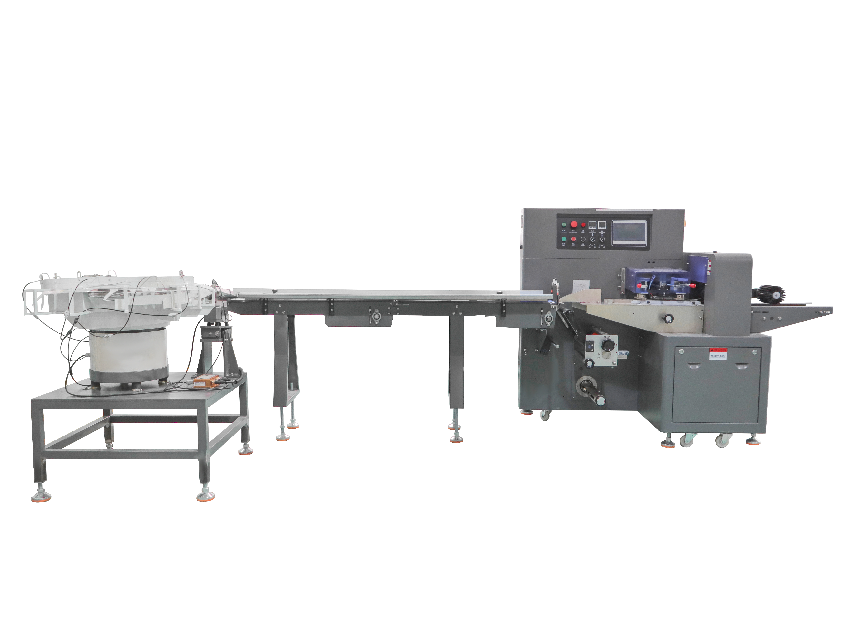

1. Vibratory Bowl Feeder System

Designed to handle lightweight plastic scoops, the vibratory feeder arranges them in a uniform orientation and delivers them accurately to the packaging line. This ensures smooth feeding without jamming or misalignment.

2. Horizontal Flow Wrapper

The horizontal packaging machine precisely wraps each scoop in a pillow-type pouch. With adjustable sealing temperature and speed, it ensures an airtight and visually appealing finish.

3. Integrated Automation

The system is fully automated from feeding to sealing, significantly reducing manual labor, minimizing contamination risks, and improving production throughput.

4. Customizable Bag Length and Film

Compatible with a range of film types and sizes, the packaging machine can be customized to meet different branding and packaging requirements.

5. Compact and Hygienic Design

Built from food-grade stainless steel, the system is compact, easy to clean, and meets hygiene regulations essential for baby product accessories.

Working Principle of the Packaging System

1. Scoop Loading

Milk powder scoops are loaded into the vibratory bowl feeder. Through vibration and spiral track design, scoops are sorted and aligned for delivery to the conveyor.

2. Feeding and Alignment

The scoops are transferred one by one onto the horizontal flow wrapper’s infeed conveyor in consistent orientation.

3. Film Feeding and Wrapping

Packaging film is unwound and shaped around each scoop. The machine then seals the back, bottom, and ends to form a complete pouch.

4. Sealing and Cutting

The pouch is heat-sealed and precisely cut into individual packages, ready for further packing or distribution.

Applications

This system is specifically designed for:

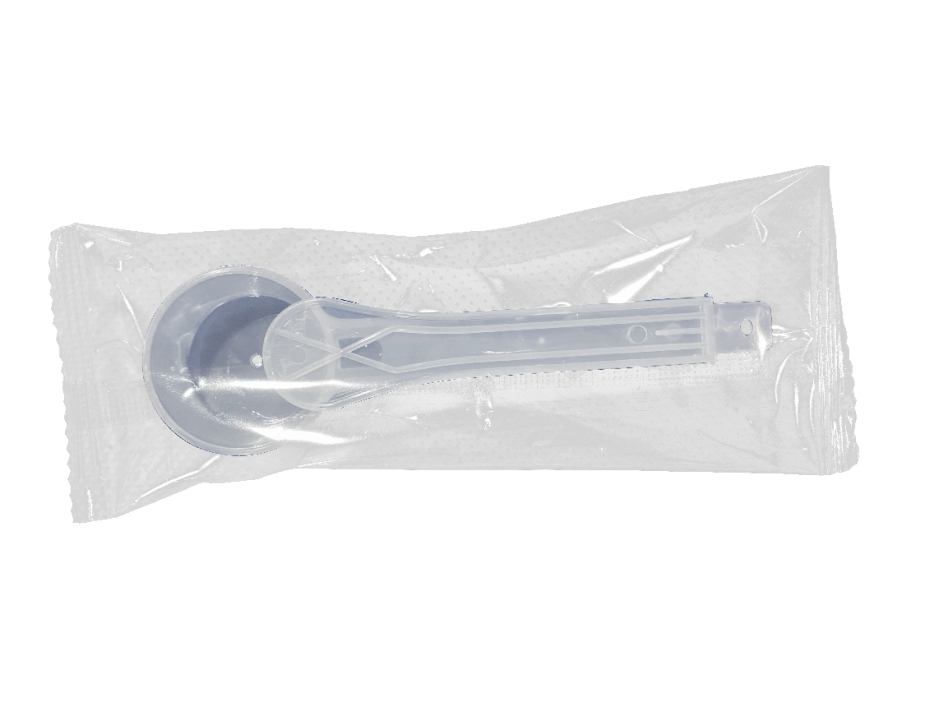

Milk Powder Scoops:Single Pack

Baby Bottle Accessories:lids, rings

Lightweight Plastic Tools:measuring spoons, droppers

Small Promotional Items:sample items for powdered formula brands

Advantages of the Horizontal Packaging Solution

Gentle and Accurate Feeding: The vibratory feeder handles fragile plastic parts without scratching or damaging them.

High-Speed Automation: Capable of packaging up to 60–100 scoops per minute, depending on product and film.

Improved Hygiene and Safety: Fully enclosed process minimizes exposure to external contamination.

Stable and Attractive Packaging: Uniform pillow packs improve shelf presence and brand consistency.

Easy Integration: Can be connected with labeling, counting, or cartoning machines to form a complete packaging line.

Conclusion

The horizontal packaging solution combining a vibratory feeder and flow wrapper is an efficient, hygienic, and scalable system ideal for packaging single milk powder scoops. It not only ensures consistent output and minimal manual intervention but also meets the growing demand for clean, precise packaging in the baby product industry. For manufacturers seeking a reliable and automated packaging solution, this system offers both performance and flexibility, making it a valuable investment for enhanced productivity and brand quality.

Get the latest price? We'll respond as soon as possible(within 12 hours)