Robotic Carton Erector + Carton Sealing Machine Line: Fully Automated Case Packing from Formation to Closure

In high-throughput warehousing, logistics, and production environments, an efficient, automated case packing system is essential to ensure speed, consistency, and minimal labor intervention. This packaging line combines a Robotic Carton Erector and a Carton Sealing Machine into a synchronized system that automates the full cycle of carton opening, bottom sealing, filling, and top sealing-- making it an ideal choice for e-commerce, FMCG, and manufacturing industries.

Key Features

This fully automated case packaging line is designed for streamlined performance and minimal human involvement. It includes:

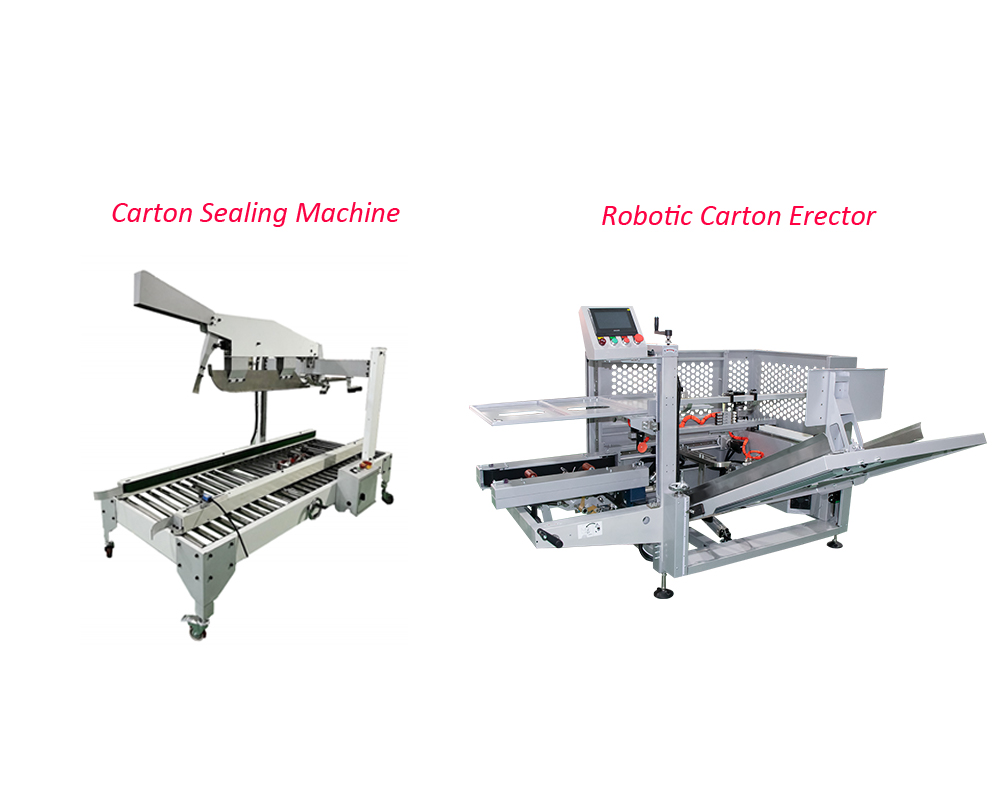

A Robotic Carton Erector that automatically picks up flat cartons, opens each box, and seals the bottom using tape. The erecting process is stable and accurate, thanks to robotic arms with programmable motion paths.

A Carton Sealing Machine positioned downstream, responsible for sealing the top of cartons once products are loaded inside. The sealing head uses durable pressure rollers and consistent taping for clean, tamper-evident closure.

A Modular Conveyor System connecting both stations, enabling smooth and aligned carton transfer between each stage, and allowing integration with manual or automatic product loading units in between.

This integration reduces downtime, standardizes sealing quality, and increases throughput, making the line suitable for both batch and continuous production operations.

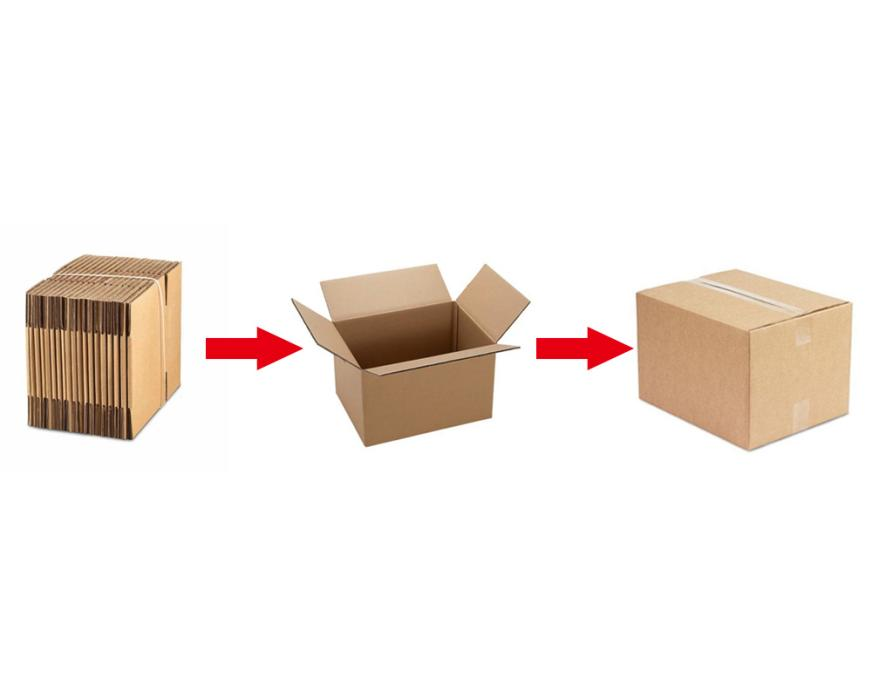

Working Process

The process begins with a magazine of flat cartons loaded into the Robotic Carton Erector. Each blank is picked, erected, and its bottom sealed automatically. The sealed empty cartons are transferred to the filling area — which can be manual or robotic, depending on the operation.

Once filled, the cartons continue along the conveyor to the Carton Sealing Machine. Here, the top flaps are folded and sealed with tape in a consistent and reliable manner. The sealed cartons are then discharged, ready for palletizing, labeling, or shipping.

This process eliminates bottlenecks in the packaging line and ensures reliable, repeatable results even with varying carton sizes or packaging cycles.

Applications

This automated sealing line is ideal for:

E-commerce order fulfillment centers

Fast-moving consumer goods factories

Food and beverage secondary packaging

Electronics and appliance box packing

Pharmaceuticals and medical supplies logistics

Any high-volume distribution warehouse requiring standardized carton handling

Benefits

Hands-Free Carton Processing

Reduces dependence on manual labor while increasing consistency in box formation and sealing.

Scalable and Customizable

Supports different carton sizes and production speeds with programmable logic and modular layout.

Minimized Downtime

Servo-driven systems and smart sensors reduce jamming, misfeeds, and sealing errors.

Reliable Taping and Closure

Uniform sealing quality enhances product protection during transport and storage.

Integrated Workflow

Seamless operation between carton erecting, filling, and top sealing reduces handling time and floor space.

Conclusion

This Robotic Carton Erector and Carton Sealing Machine line offers a highly efficient solution for companies looking to automate their end-of-line packaging process. By integrating carton forming and closure into one streamlined workflow, it ensures high-speed operation, labor cost savings, and consistent packaging quality —making it the ideal setup for today’s fast-paced production and distribution environments.

Get the latest price? We'll respond as soon as possible(within 12 hours)