Vacuum Packaging Solution for Mixed Mineral Granules: Multi-Weigher Integration with Premade Pouch Packaging Machine

In the mining and mineral product industries, achieving dust-free, moisture-proof, and contamination-free packaging is critical for maintaining material quality and transportation safety. Our vacuum pouch packaging system for small mineral granules offers a highly efficient and precise solution designed to handle mixed batches of mineral particles. The system combines multiple feeding and weighing components with an advanced vacuum pouch machine, delivering industrial-grade sealing and presentation.

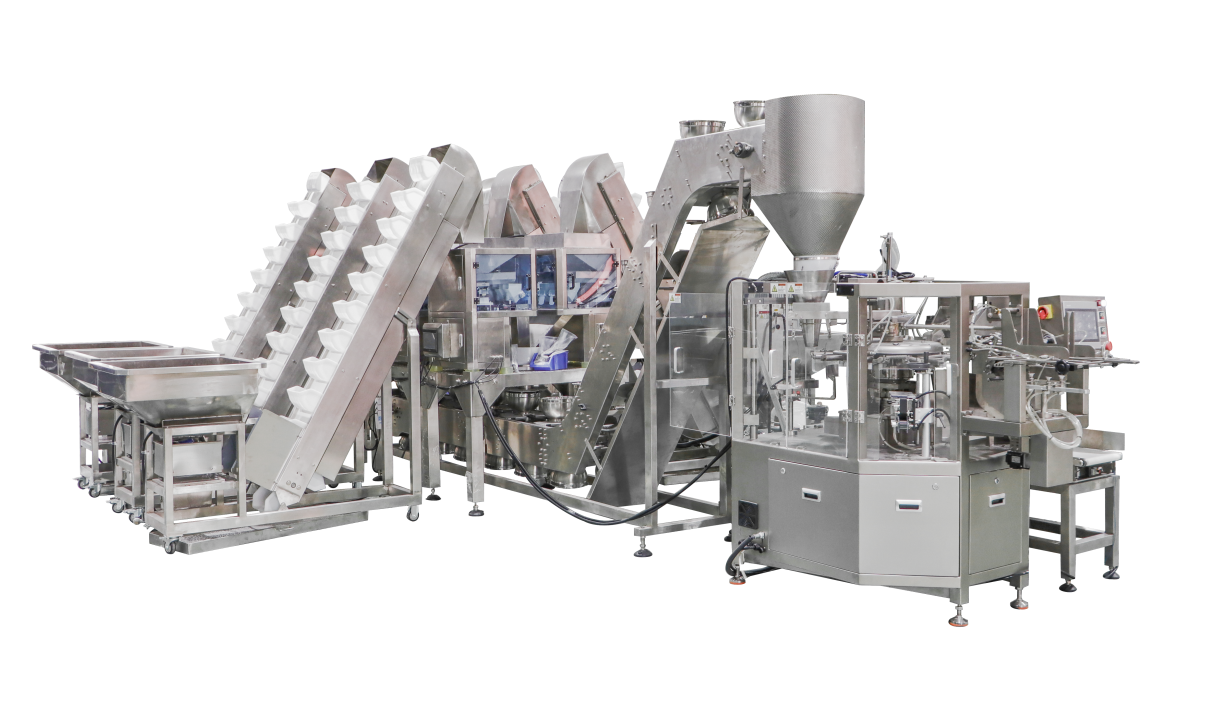

Integrated Equipment Line

This packaging system features six bucket elevators paired with six small-scale electronic weighers, strategically aligned in three opposing rows (two units per row). Each pair of elevator and weigher works in tandem to transport and portion different types of mineral granules, allowing for customizable mixing ratios before final packaging. The multi-line configuration not only increases throughput but also supports flexible material handling for various granular types and densities.

Once the weighing process is completed, the materials are collected and transferred via a bowl-type elevator, which gently lifts the pre-weighed granules to the vacuum pouch packing machine. This method ensures smooth product transition, reduces material loss, and maintains uniform feeding into the packaging station.

Pouch Packaging Machine with Vacuum Function

At the heart of this system is a fully automatic rotary pouch packaging machine integrated with a targeted vacuum extraction mechanism. After the granule mixture is accurately filled into the preformed pouch, an air suction tube is inserted into the pouch to evacuate the internal air. Once the air is removed, the machine immediately performs heat sealing, locking in product freshness and preventing oxidation or moisture ingress.

This method offers a streamlined and efficient vacuum packaging process, maintaining product integrity while maximizing output. The machine supports various pouch styles such as flat-bottom bags, stand-up pouches, and zipper bags, making it ideal for warehousing, distribution, and retail-ready presentation.

Advantages of the Solution

High Capacity and Precision: Six weighing stations allow for simultaneous multi-material dosing, improving accuracy and production speed.

Automated Vacuum Sealing: Built-in vacuum technology ensures extended shelf life and protection for sensitive mineral materials.

Flexible Material Handling: Suitable for quartz sand, fine crushed stones, colored mineral chips, and other granular materials.

Reduced Dust and Contamination: Fully enclosed operation with minimal manual contact enhances cleanliness and worker safety.

Scalable and Modular Design: Ideal for factories with diversified SKUs or frequent batch changeovers.

Applications

This packaging line is ideal for industries dealing with:

Decorative mineral stones

Aquarium substrate materials

Specialty construction aggregates

Colored gravel for landscaping

Laboratory or sample mineral products

Conclusion

By integrating precision weighing, multi-line feeding, and vacuum pouch sealing, this automated packaging system provides a powerful solution for companies handling granular mineral products. With its clean design, high throughput, and material protection capabilities, it helps businesses improve efficiency, reduce labor costs, and ensure consistent product quality across every batch.

Get the latest price? We'll respond as soon as possible(within 12 hours)