Medical Bandage Pillow Packing Machine: Automated Solution with Centrifugal Sorting Feeder

Medical Bandage Pillow Packing Machine: Automated Solution with Centrifugal Sorting Feeder

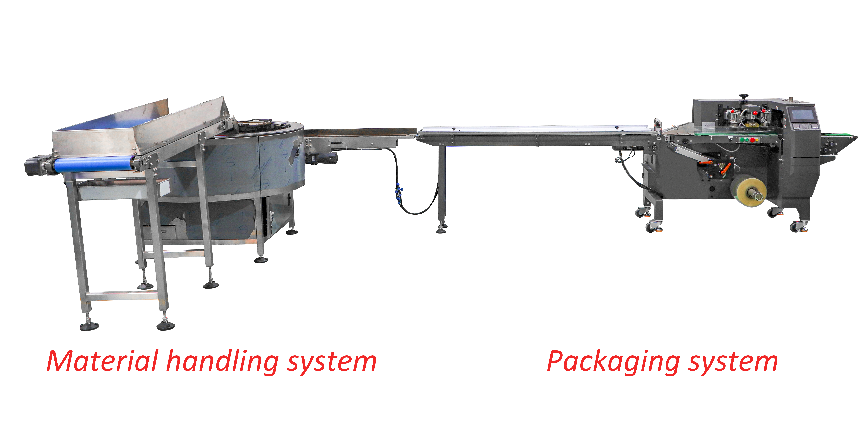

This packaging solution uses a centrifugal sorting feeder combined with a pillow packing machine to provide an efficient, hygienic, and fully automated method for packaging medical bandages. The system ensures smooth product handling, accurate positioning, and consistent packaging results, ideal for sterile and high-volume medical supply environments.

Packaging process

The process begins with a conveyor belt that transfers the freshly rolled medical bandages from the production line into a centrifugal sorting disc. This rotating disc gently spins and aligns the bandages into the correct orientation. Through the action of centrifugal force and mechanical guidance, the bandages are spaced evenly and guided smoothly onto the infeed conveyor of the pillow packing machine.

Once aligned, the bandages are transferred to the pillow packing machine. Here, the packaging film is wrapped around each bandage roll, heat-sealed, and cut into individual packages. The pillow packing machine supports high-speed continuous operation, ensuring efficient throughput without compromising sealing integrity or appearance.

The entire system is built with medical-grade stainless steel and complies with hygienic production standards. The automated feeding and packaging significantly reduce manual labor, contamination risk, and operational inconsistencies.

Key Features

Centrifugal Sorting Feeder: Automatically aligns and spaces products for smooth feeding.

Hygienic Conveyor Feeding: Transfers bandages gently and safely to the feeder.

High-Speed Pillow Packing: Ensures airtight sealing and efficient production.

Compact & Integrated Design: Saves space and reduces operational complexity.

Medical-Grade Build: Stainless steel structure meets cleanliness and safety standards.

User-Friendly Interface: Touchscreen controls for quick adjustment and monitoring.

Applications

Medical bandages (elastic rolls, gauze rolls)

Sterile dressings

Other cylindrical medical disposables

Advantages

Reduces manual sorting and labor cost

Ensures product hygiene and avoids contamination

Delivers consistent package size and appearance

Minimizes error in feeding and alignment

Improves productivity in sterile environments

Conclusion

For manufacturers in the medical industry, the centrifugal feeder + pillow packaging machine offers a robust, efficient, and hygienic solution for bandage packaging. Its automated feeding, accurate orientation, and high-speed packaging make it an essential choice for large-scale medical product packaging lines.

Get the latest price? We'll respond as soon as possible(within 12 hours)