Multi-Stick Liquid Sachet Pillow Packing Machine: Precision Group Packaging with Custom Conveyor & Pusher System

Multi-Stick Liquid Sachet Pillow Packing Machine: Precision Group Packaging with Custom Conveyor & Pusher System

Stick pack liquid sachets—such as concentrated coffee, liquid supplements, and nutritional gels—are widely favored in the food, beverage, and health industries for their portability and controlled dosage. To enhance their secondary packaging efficiency and retail presentation, manufacturers often group 6–8 stick sachets into one package. Our multi-stick liquid sachet pillow packing solution offers an automated, hygienic, and efficient way to achieve this—with a custom-designed conveyor system and an integrated pusher unit that ensures seamless, neat, and stable packaging.

Key Features:

1. Tailored for Liquid-Filled Stick Packs

This solution is ideal for long, narrow sachets pre-filled with liquid products. Whether sourced from upstream multi-lane stick pack machines or manual loading lines, the system handles them gently to prevent spillage or breakage.

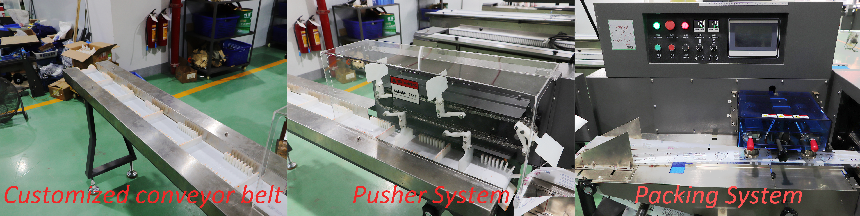

2. Custom Conveyor with Tray Segmentation

The specially designed infeed conveyor includes segmented trays that guide and organize sachets into fixed groups. This customization prevents overlapping and ensures consistent alignment before entering the packing stage.

3. Auxiliary Pusher Device at Conveyor End

At the end of the conveyor, an integrated pusher mechanism gently but firmly pushes each sachet group into the forming area of the pillow packaging machine. This ensures that every group enters the film in a compact, flat, and uniform orientation, improving seal quality and pack appearance.

4. Precise Pillow Bag Formation & Sealing

A film roll mounted at the back of the machine unwinds and wraps around the sachet stack. The machine completes longitudinal and transverse sealing with high precision, using controlled temperature and pressure to guarantee a clean, leak-free result.

5. User-Friendly Smart Controls

The machine is operated via a PLC-based touchscreen interface. Operators can easily adjust grouping quantities, sealing parameters, and machine speed, with real-time monitoring and error alarms.

Working Flow Overview:

1. Sachet Feeding: Sachets are loaded onto the segmented custom conveyor (manual or automatic).

2. Grouping & Stacking: The conveyor arranges the sachets into desired group sizes (e.g., 6–8).

3. Pushing into Film Zone: The pusher at the conveyor’s end pushes the sachets into the film forming area in a flat, stacked manner.

4. Bag Forming & Sealing: The film is wrapped, sealed, and cut to create a clean pillow pack.

5. Output: Finished packs are discharged for collection or downstream automation.

Application Scope:

Liquid coffee sticks

Honey or fruit syrup sachets

Vitamin or beauty supplement sticks

Energy gels

Liquid herbal products

Concentrated flavoring sticks

Benefits of Our Packaging Solution:

Perfect for Grouped Packaging: Consolidates multiple stick sachets into retail-ready units.

Stability & Neatness: The pusher ensures tight, clean pack formation with no misalignment.

Leak-Free Sealing: Accurate temperature control and pressure ensure reliable closure for liquid products.

Customized for Your Product: The infeed system and pushing device can be tailored to your sachet size and grouping requirement.

Improved Efficiency: Reduces manual labor, speeds up packing, and boosts overall production throughput.

Conclusion:

For manufacturers seeking a clean, automated, and precise method to group-pack liquid stick sachets, this customized pillow packaging solution is the answer. With its engineered conveyor and auxiliary pushing system, it ensures uniform, reliable packaging—perfect for retail or bulk distribution.

Get the latest price? We'll respond as soon as possible(within 12 hours)