Metal Hardware Ring Horizontal Packaging Machine: Tailored Solution for Single-Side Sealed Ring Parts

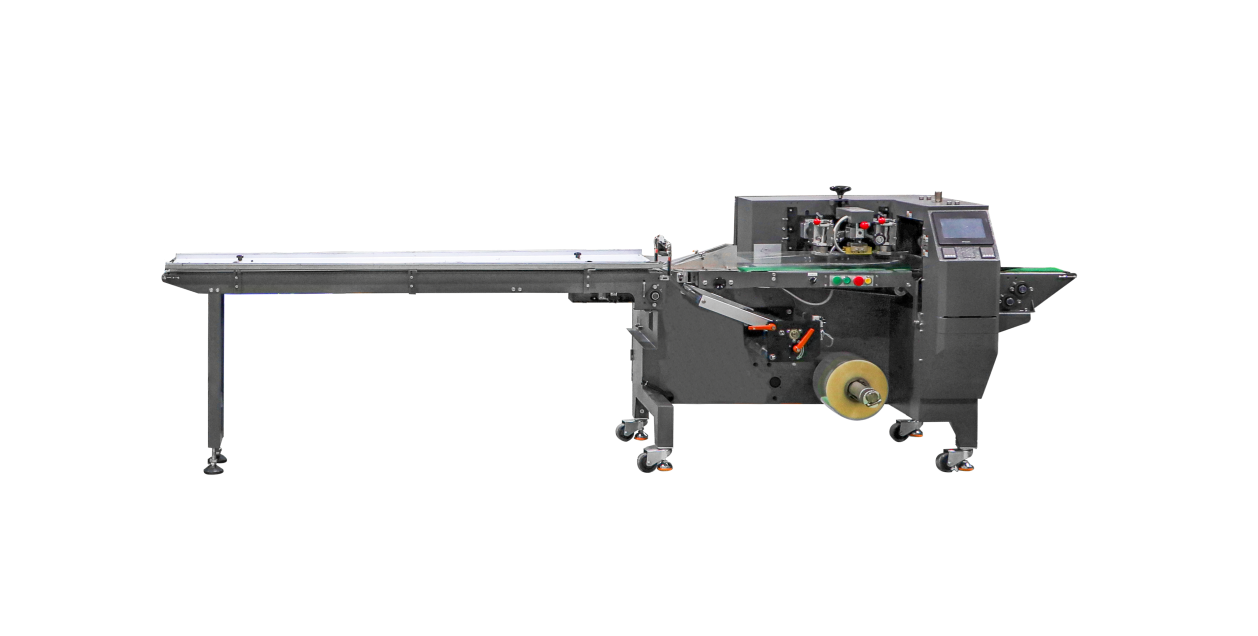

In the hardware industry, efficient and protective packaging plays a crucial role in preserving product integrity during transportation and storage. For circular metal components with a hollow center—such as hardware rings with approximately 10 cm in diameter—a specialized pillow-type packaging solution is required. This packaging must not only protect the product but also accommodate its unique shape while allowing for visibility or accessibility. Our customized horizontal packaging machine offers a single-side sealing configuration, perfectly suited for these ring-shaped hardware parts.

Key Features

1. Customized for Circular Hardware Parts

Specially designed to package ring-shaped metal parts with a central opening and around 10 cm in diameter. The feeding and film handling systems are adjusted to maintain the part’s shape and position during packaging.

2. Single-Side Sealing

Unlike standard pillow packs, this solution seals only one side of the package. The other side remains open or exposed, allowing for easy product identification or manual handling while still offering partial protection and grouping.

3. Stable and Accurate Feeding

The packaging machine uses a flat-belt or tray-type conveyor to stably transport the metal rings without flipping or misalignment. Optional guiding rails or fixtures are available to ensure positioning accuracy.

4. Heavy-Duty Design

Built with industrial-grade materials to support the weight and impact of hardware components. The sealing jaws and film feeding mechanisms are reinforced for long-term use.

5. Flexible Film Material Options

Supports PE, composite, and anti-rust films depending on the corrosion protection needs of the hardware parts.

6. User-Friendly Operation

Equipped with a touchscreen control panel for setting bag length, sealing temperature, and packaging speed. Easy to operate, clean, and maintain.

Working Process

1. Feeding

Circular hardware rings are conveyed one by one onto the machine’s infeed conveyor.

2. Film Unwinding & Wrapping

The packaging film is unwound from the rear film rack and wraps around the product from the bottom, leaving one side exposed.

3. Sealing

A horizontal sealing jaw seals the trailing edge of the package, securing the ring in place. The open side remains unsealed according to the custom configuration.

4. Cutting & Discharge

The film is cut into individual packs, and the packaged rings are discharged onto the outfeed conveyor for boxing or collection.

Applications

This horizontal packaging solution is ideal for:

Ring-shaped hardware parts

Pipe connectors and fittings

Gaskets and mechanical seals

Circular blade holders or flange parts

It is suitable for manufacturers and suppliers of industrial components who need protective yet accessible packaging solutions for logistics and warehousing.

Advantages of the Single-Side Seal horizontal Packaging Machine

Partial Protection with Accessibility: One-side sealing allows quick inspection, assembly, or manual pickup.

High Efficiency: Automated feeding and sealing improve production speed while reducing labor costs.

Minimal Damage Risk: The product remains stable throughout the process, minimizing scratches or deformation.

Customizable Layout: Machine dimensions, conveyor type, and film width can be tailored to different hardware ring sizes.

Conclusion

For ring-shaped hardware components requiring practical, protective, and efficient packaging, our single-side seal horizontal packaging machine offers an ideal solution. Combining robust design with tailored automation, it ensures smooth handling, packaging consistency, and cost efficiency. Whether for B2B shipments or retail kitting, this system adds professional packaging value to any industrial operation.

Get the latest price? We'll respond as soon as possible(within 12 hours)