Olives with Liquid Premade Pouch Packaging Machine: Integrated Solution for Solid-Liquid Mixed Packing

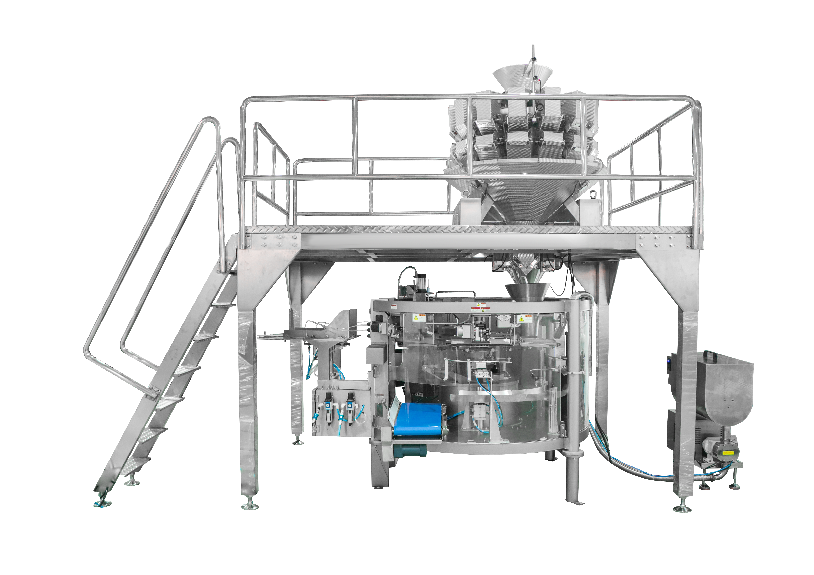

Packaging solid-liquid mixtures such as olives in brine poses unique challenges in the food industry—it requires precise solid dosing, hygienic liquid filling, and leak-proof sealing. To address these needs, we provide a fully automatic premade pouch packaging solution consisting of a rotary doypack machine, a 14-head embossed surface weigher, a liquid filling pump with a storage tank, and a reinforced weigher platform. This integrated system ensures clean, accurate, and efficient packaging of olives with water or oil, delivering visually appealing, shelf-ready packages for retail markets.

Detailed Description

1. Product Requirements

Olives are often packed with liquid (water or oil) to preserve freshness, enhance flavor, and extend shelf life. The packaging system must prevent leaks, ensure hygienic conditions, and maintain portion accuracy.

2. Packaging System Configuration

Premade Pouch Packaging Machine: This rotary system automatically opens, fills, seals, and discharges prefabricated pouches. It is compatible with doypacks, flat pouches, and zipper bags.

14-Head Embossed Surface Weigher: Specially designed with textured buckets to handle slippery or wet products like olives. Ensures accurate portioning of the solid content before filling.

Liquid Filling Pump + Storage Tank: The liquid component (water or oil) is stored in a stainless steel tank and pumped through food-grade lines into the pouch after solid filling. The pump is precisely synchronized with the weigher.

Weigher Support Platform: A stainless steel structure that supports the multihead weigher and ensures stable operation and operator safety.

Working Principle

√ The olives are delivered to the weigher via a bucket elevator.

√The weigher doses the exact quantity of olives and releases them into the open pouch.

√The liquid pump injects the required volume of water into the same pouch.

√The premade pouch machine seals the bag securely using heat sealing technology.

The finished pouch is discharged for boxing or retail distribution.

Packaging Benefits

No Leakage: Dual filling (solid first, liquid second) with precise sealing avoids leaks.

Hygienic Design: All parts in contact with product are food-grade stainless steel.

Consistent Quality: Advanced control system ensures every pouch meets weight and fill requirements.

Flexibility: Suitable for various pouch sizes and product types including other pickled vegetables or fruit in syrup.

Automation: Reduces labor costs, boosts throughput, and maintains product integrity.

Applications

This solution is ideal for packaging:

Olives in water or oil

Pickled vegetables (e.g., garlic, chili)

Fruits in syrup

Cooked beans or legumes in brine

Ready-to-eat condiments with liquid content

Conclusion

For producers of olives or other solid-liquid food products, this integrated premade pouch packaging system offers a reliable, clean, and efficient solution. With precise weighing, hygienic liquid filling, and consistent pouch sealing, it ensures each product reaches the consumer in optimal condition—enhancing both shelf appeal and operational efficiency.

Get the latest price? We'll respond as soon as possible(within 12 hours)