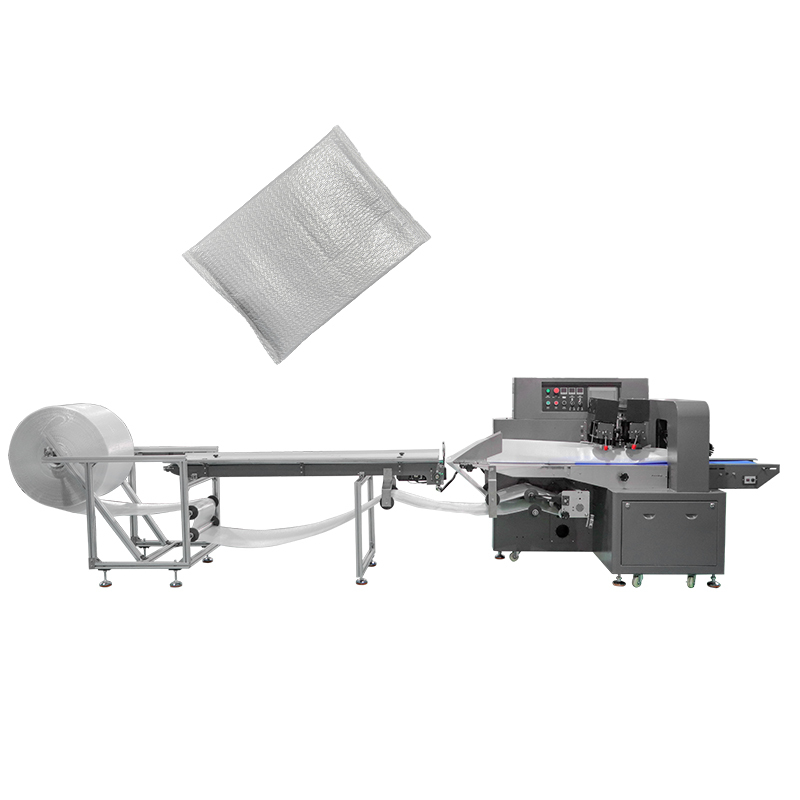

Horizontal Flow Packing Machine for Bubble Film

The horizontal flow packing machine for bubble film, or HFFS packing machine, is a valuable asset in the packaging industry. Its ability to provide efficient packaging with enhanced product protection makes it suitable for a wide range of applications. As technology evolves, this machine will continue to play a crucial role in meeting the packaging needs of various industries.

Details

Horizontal Flow Packing Machine for Bubble Film

Bag width | 30-110mm | Weight range | 30-1000g | |

Film material | OPP/CPP.OPP/PE/PET | Functions | Filling,Labeling,Sealing | |

Speed | Max 230bags/min | Machine weight | 500KG | |

Power | 220V 2.4KW | Packing items | Carrot,banana.cucumber etc | |

Machine size | 3770*720*1420mm(L*W*H) | Film width | Max 250mm | |

Machine material | Stainless steel 304/316L for option | |||

I. Overview

The horizontal flow packing machine for bubble film functionality is designed to package a wide range of products in a horizontal orientation while simultaneously incorporating bubble wrap for enhanced protection. The HFFS packing machine forms a continuous tube of packaging material, fills it with the product, seals it horizontally, and then cuts the filled and sealed packages into individual units. The bubble wrap component is integrated into the process to provide cushioning and shock - absorption, ensuring that the packaged products remain safe during transportation and storage.

II. Working Principles

Film and Bubble Wrap Feeding

The packaging process begins with the unwinding of the main packaging film and the bubble wrap from their respective rolls. The films are fed into the machine through a series of rollers that guide them towards the forming area. The bubble wrap is typically positioned either on the inside or outside of the main packaging film, depending on the design of the machine and the desired packaging configuration.

Forming the Package:

As the films move forward, they pass through a forming tube. The main packaging film is shaped into a continuous tube around the product feeding area, while the bubble wrap is either wrapped around the product or integrated into the tube structure. This forming process is carefully controlled to ensure that the films are properly aligned and that the bubble wrap provides adequate coverage and protection.

Product Filling:

Products to be packaged are conveyed into the machine in an organized manner. The product filling mechanism is synchronized with the movement of the films to ensure that each product is accurately placed within the formed tube. Whether it's small electronic components, fragile items, or regular consumer goods, the machine can handle a variety of products with different shapes and sizes.

Sealing:

Once the products are filled into the tube, the machine performs two types of sealing: longitudinal and cross - sealing. Longitudinal sealing occurs along the edge of the main packaging film tube to create a continuous, closed tube. Cross - sealing is then performed at regular intervals to create individual packages. The sealing process is crucial as it not only encloses the product but also secures the bubble wrap in place, ensuring that it provides continuous protection.

Cutting:

After sealing, the filled and sealed packages are cut into discrete units. The cutting mechanism, which can be a mechanical blade or a hot - knife, makes precise cuts to separate the packages. The cut packages are then ready for further processing, such as labeling or boxing.

III. Key Components

Film and Bubble Wrap Unwinding Systems

These systems are responsible for smoothly unwinding the main packaging film and the bubble wrap from their rolls. They include tension control mechanisms to maintain a consistent tension throughout the packaging process, preventing film wrinkles and misalignment.

Forming Tube and Shoulder

The forming tube and shoulder are essential for shaping the packaging film and integrating the bubble wrap. They are precision - engineered to ensure accurate film forming and proper bubble wrap placement.

Product Feeding Mechanism:

The product feeding mechanism can vary depending on the type of product. It may include conveyor belts, vibratory feeders, or other specialized feeding devices to ensure that products are evenly spaced and accurately placed within the packaging.

Sealing Jaws:

The sealing jaws, both longitudinal and cross - sealing, are heated to the appropriate temperature to melt and bond the packaging film. They are designed to provide strong, reliable seals that keep the product and bubble wrap securely enclosed.

Cutting Device:

The cutting device is responsible for separating the filled and sealed packages. It is designed to make clean, precise cuts, ensuring that the packages have a neat appearance.

Control System:

The control system is the brain of the horizontal flow packing machine. It coordinates all the functions of the machine, including film and bubble wrap feeding, product filling, sealing, and cutting. It allows operators to adjust parameters, monitor the packaging process, and troubleshoot any issues that may arise.

IV. Applications

Electronics Industry:

In the electronics industry, where products are often delicate and sensitive to shock and vibration, the horizontal flow packing machine with bubble wrap functionality is invaluable. It can be used to package small electronic components such as circuit boards, connectors, and microchips. The bubble wrap provides the necessary cushioning to protect these items during shipping and handling.

Fragile Goods Packaging:

For fragile items like glassware, ceramics, and figurines, this packaging machine offers an ideal solution. The bubble wrap effectively absorbs shocks and impacts, reducing the risk of damage to the products. It ensures that these fragile goods reach their destination in perfect condition.

Consumer Goods:

In the consumer goods sector, products such as cosmetics, toys, and small household items can benefit from the protection offered by the bubble wrap. The HFFS packing machine can package these items efficiently while providing an extra layer of security, enhancing customer satisfaction.

Pharmaceutical Industry:

Although the primary focus in pharmaceutical packaging is often on sterility and product integrity, the added protection of bubble wrap can be useful for certain products. For example, vials of sensitive medications or medical devices can be packaged using this machine to prevent breakage during transportation.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)