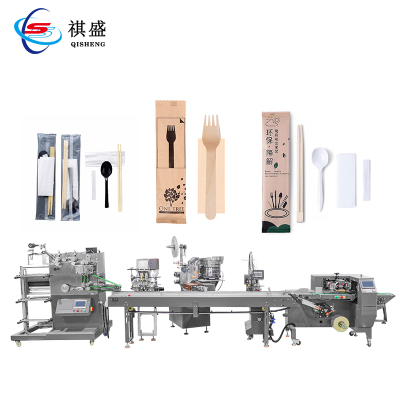

Horizontal Flow Packing Machine with a Sorting Disc

The horizontal flow packing machine with a sorting disc, or HFFS packing machine, is a powerful and versatile packaging solution that offers numerous benefits to various industries. Its ability to combine product sorting with efficient packaging processes makes it an invaluable asset in modern manufacturing. As technology continues to advance, we can expect these machines to become even more sophisticated, driving innovation and growth in the packaging industry.

Details

Horizontal Flow Packing Machine with a Sorting Disc

Bag width | 30-110mm | Weight range | 30-1000g | |

Film material | OPP/CPP.OPP/PE/PET | Functions | Filling,Labeling,Sealing | |

Speed | Max 230bags/min | Machine weight | 500KG | |

Power | 220V 2.4KW | Packing items | Carrot,banana.cucumber etc | |

Machine size | 3770*720*1420mm(L*W*H) | Film width | Max 250mm | |

Machine material | Stainless steel 304/316L for option | |||

I. Understanding the Horizontal Flow Packing Machine with a Sorting Disc

A horizontal flow packing machine with a sorting disc is a sophisticated piece of equipment designed to package products in a horizontal orientation. It combines the processes of product sorting, film forming, product filling, sealing, and cutting into a continuous and automated operation. The sorting disc is a key component that helps in organizing and arranging the products before they enter the packaging process, ensuring a smooth and efficient flow. The HFFS packing machine forms a tube of packaging material, fills it with the sorted products, seals the tube horizontally, and then cuts the filled and sealed tube into individual packages.

II. Working Principles of the Horizontal Flow Packing Machine with a Sorting Disc

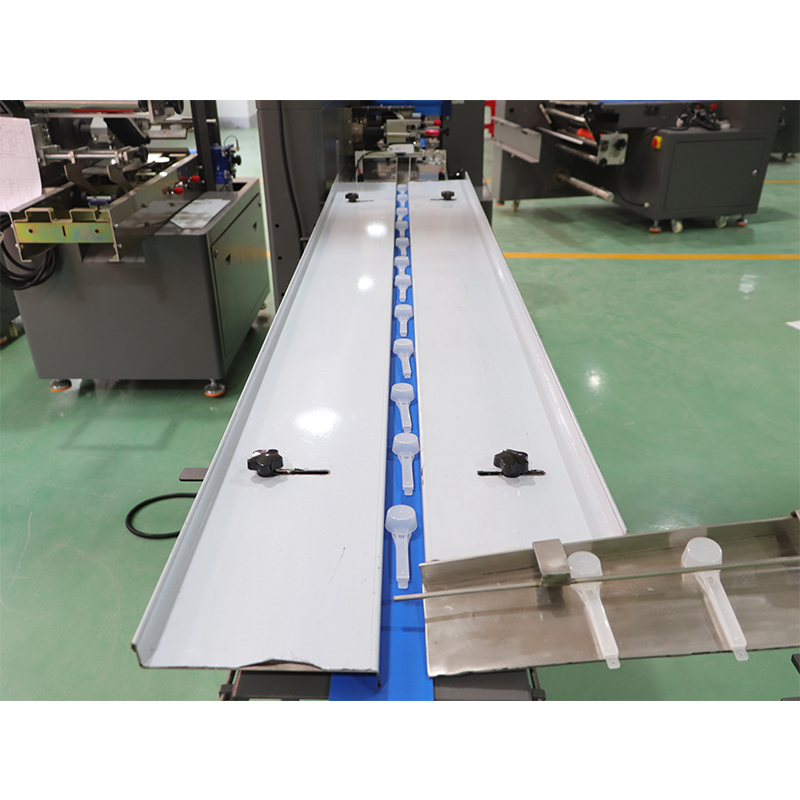

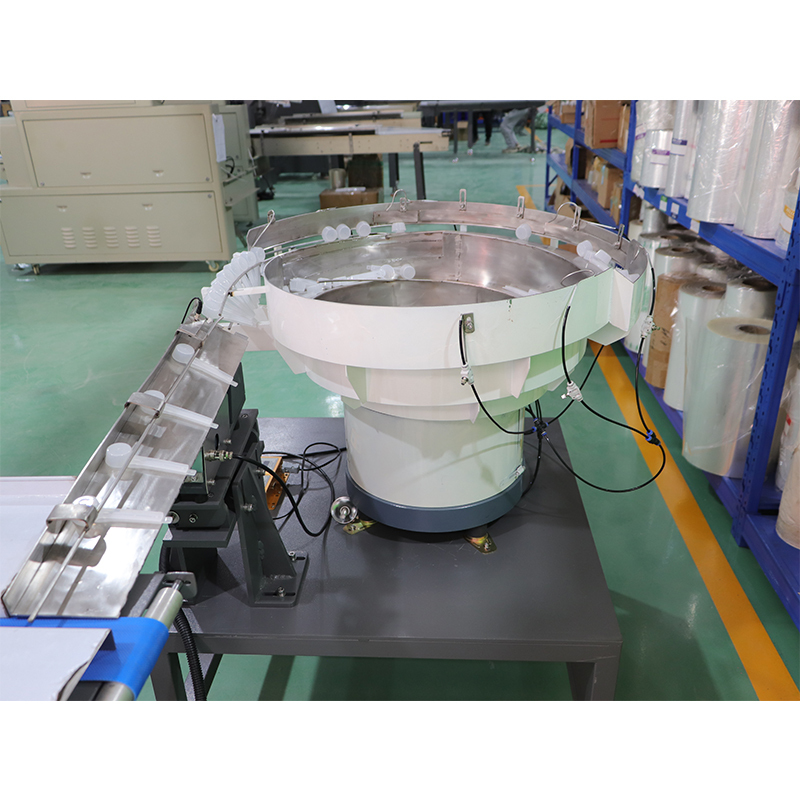

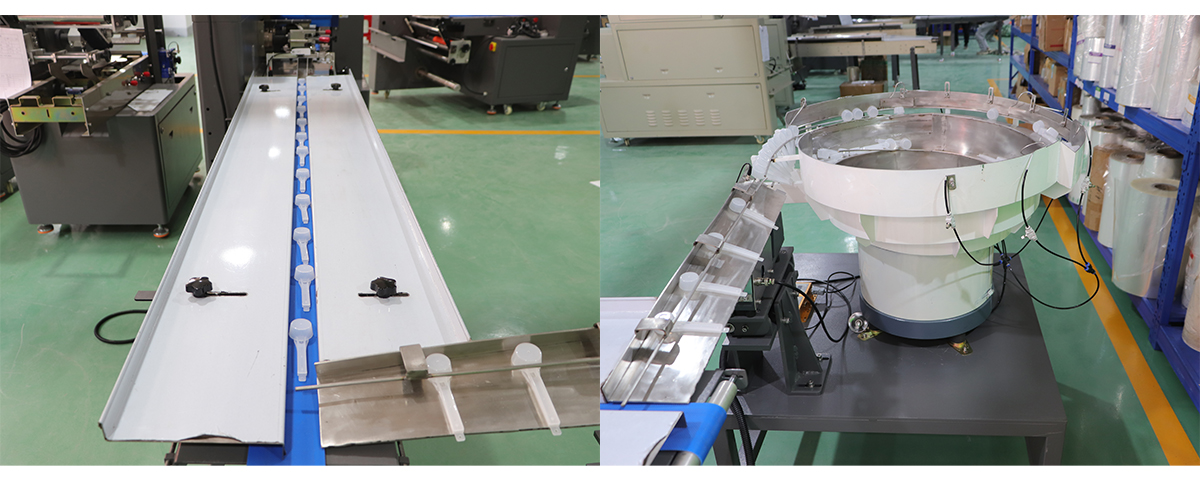

Product Sorting and Feeding

The journey of a product through the horizontal flow packing machine begins at the sorting disc. The sorting disc is equipped with a series of pockets or channels that are designed to hold and arrange the products in a specific pattern. Products are fed into the sorting disc, either manually or through an automated feeding system. The disc rotates, and as it does so, it aligns the products in a single file, ready for the next stage of the packaging process. This initial sorting step is crucial as it ensures that the products are evenly spaced and properly oriented, which is essential for accurate filling and sealing.

Film Unwinding and Forming

Simultaneously, the packaging film, usually in roll form, is unwound from a reel and fed into the machine. The film passes through a series of rollers that guide it towards the forming tube. As the film approaches the forming tube, it is shaped into a continuous tube around the product feeding area. The forming process is carefully controlled to ensure that the film is properly aligned and forms a tight - fitting tube around the products.

Product Filling

Once the products are sorted and the film is formed into a tube, the products are filled into the tube at the appropriate intervals. The filling mechanism is synchronized with the rotation of the sorting disc and the movement of the film to ensure that each product is accurately placed within the tube. Depending on the type of product, different filling methods may be used, such as gravity filling for solid products or piston filling for viscous products.

Sealing

After the products are filled into the tube, the machine performs two types of sealing: longitudinal sealing and cross - sealing. Longitudinal sealing occurs along the edge of the film tube to create a continuous, closed tube. This is typically done using heated sealing jaws that melt and bond the edges of the film together. Cross - sealing is then performed at regular intervals to create individual packages. The cross - sealing jaws also heat and press the film to form a strong seal, ensuring that the products are securely enclosed within the package.

Cutting

Once the packages are sealed, they are cut into discrete units. The cutting mechanism, which can be a mechanical blade or a hot knife, separates the filled and sealed packages from the continuous tube. The cut packages are then ready for further processing, such as labeling or boxing.

III. Key Components of the Horizontal Flow Packing Machine with a Sorting Disc

Sorting Disc

The sorting disc is the heart of the machine's product organization system. It is precision - engineered to handle products of various shapes and sizes. The design of the pockets or channels on the disc can be customized according to the specific product requirements, ensuring efficient sorting and feeding.

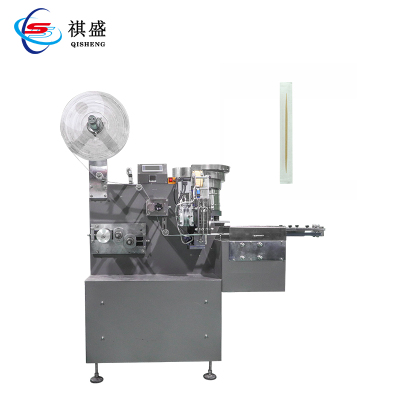

Film Unwinding and Tension Control System

This system is responsible for unwinding the packaging film from the reel and maintaining a consistent tension throughout the packaging process. Proper tension control is essential to prevent film wrinkles, misalignment, and other issues that could affect the quality of the packaged products.

Forming Tube and Shoulder

The forming tube and shoulder are crucial for shaping the flat packaging film into a tube. They are made of high - quality materials to withstand the wear and tear of continuous operation and ensure accurate film forming.

Filling Mechanism

The filling mechanism is tailored to the type of product being packaged. It can include volumetric fillers, weighing fillers, or other types of filling devices, depending on the product's characteristics and packaging requirements.

Sealing System

The sealing system consists of the longitudinal and cross - sealing jaws. These jaws are heated to the appropriate temperature to melt and bond the packaging film. The sealing system is designed to provide strong, leak - proof seals, ensuring the freshness and integrity of the packaged products.

Cutting Mechanism

The cutting mechanism is responsible for separating the filled and sealed packages from the continuous tube. It is designed to make clean, precise cuts, ensuring that the packages have a neat appearance.

Control System

The control system is the brain of the horizontal flow packing machine. It coordinates all the functions of the machine, including the rotation of the sorting disc, film unwinding, product filling, sealing, and cutting. The control system allows operators to adjust parameters, monitor the packaging process, and troubleshoot any issues that may arise.

IV. Applications of the Horizontal Flow Packing Machine with a Sorting Disc

Food Industry

In the food industry, the HFFS packing machine with a sorting disc is widely used to package a variety of products. For example, it can be used to package snacks like potato chips, pretzels, and nuts. The sorting disc ensures that the irregularly shaped snacks are evenly spaced and properly filled into the packaging. It is also used for packaging baked goods such as cookies and biscuits, as well as frozen foods like dumplings and spring rolls.

Pharmaceutical Industry

The pharmaceutical industry requires high precision and strict quality control in packaging. The horizontal flow packing machine with a sorting disc is used to package tablets, capsules, and other small pharmaceutical products. The sorting disc helps in arranging the products accurately, ensuring that each package contains the correct number of items. The machine's sealing system provides a sterile and secure packaging environment, meeting the stringent requirements of the pharmaceutical industry.

Cosmetic Industry

Cosmetic products such as lip balms, small bottles of perfume, and makeup samples can be efficiently packaged using the HFFS packing machine with a sorting disc. The sorting disc can handle the small and delicate cosmetic items, arranging them neatly for packaging. The machine's ability to produce high - quality, aesthetically pleasing packages makes it suitable for the cosmetic industry, where product presentation is crucial.

Hardware and Electronics Industry

Small hardware components like screws, nails, and washers, as well as electronic parts such as resistors and capacitors, can be packaged using this machine. The sorting disc organizes the tiny components, ensuring accurate filling into the packaging. The machine's sealing system protects the components from damage and contamination during storage and transportation.

Stationery Industry

Stationery items like paper clips, erasers, and small notebooks can be packaged using the horizontal flow packing machine with a sorting disc. The sorting disc helps in arranging the stationery products in an orderly manner, and the machine can produce attractive packages for retail sale.

V. Advantages of the Horizontal Flow Packing Machine with a Sorting Disc

Increased Productivity

The integration of the sorting disc into the horizontal flow packing machine streamlines the packaging process. It eliminates the need for manual sorting and arranging of products, reducing labor costs and increasing the packaging speed. The machine can operate continuously, producing a large number of packaged products in a short amount of time, making it ideal for high - volume production.

Improved Packaging Accuracy

The sorting disc ensures that the products are evenly spaced and properly oriented before filling. This leads to accurate filling and sealing, reducing the number of defective packages. The precise control of the machine's sealing and cutting mechanisms also contributes to the production of high - quality packages with consistent dimensions.

Versatility

The horizontal flow packing machine with a sorting disc is highly versatile and can be adapted to package a wide range of products. The design of the sorting disc can be customized to handle products of different shapes and sizes, and the machine can work with various types of packaging materials, including plastic films, laminates, and aluminum foils.

Enhanced Product Safety

The machine's sealing system provides strong and reliable seals, protecting the products from moisture, dust, and other external factors. This is especially important for products in the food and pharmaceutical industries, where product safety and freshness are paramount.

Cost - Effectiveness

Although the initial investment in a horizontal flow packing machine with a sorting disc may be significant, the long - term cost savings are substantial. The machine's high productivity, reduced labor requirements, and minimized packaging waste contribute to a lower cost per packaged unit, making it a cost - effective solution for many businesses.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)