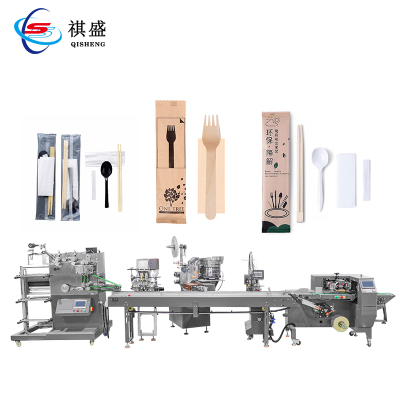

Horizontal Flow Packing Machine with a Coding Device

The horizontal flow packing machine with a coding device, or HFFS packing machine, is a versatile and efficient packaging solution that offers numerous benefits to various industries. Its ability to combine multiple packaging functions with accurate coding capabilities makes it an indispensable tool for modern packaging operations. As technology continues to advance, we can expect these machines to become even more sophisticated, further enhancing their performance and contributing to the growth of the packaging industry.

Details

Horizontal Flow Packing Machine with a Coding Device

| Bag width | 30-110mm | Weight range | 30-1000g | |

| Film material | OPP/CPP.OPP/PE/PET | Functions | Filling,Labeling,Sealing | |

| Speed | Max 230bags/min | Machine weight | 500KG | |

| Power | 220V 2.4KW | Packing items | Carrot,banana.cucumber etc | |

| Machine size | 3770*720*1420mm(L*W*H) | Film width | Max 250mm | |

| Machine material | Stainless steel 304/316L for option | |||

I. Overview of the Horizontal Flow Packing Machine with a Coding Device

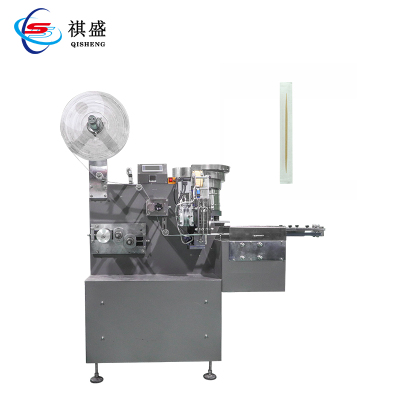

A horizontal flow packing machine with a coding device is an integrated system designed to package products in a horizontal orientation while simultaneously allowing for the addition of coding information on the packaging material. The HFFS packing machine forms a continuous tube of packaging film, fills it with the product, seals it horizontally, and then cuts the filled and sealed packages into individual units. The coding device, which can be an inkjet printer, thermal transfer printer, or laser coder, is incorporated into the machine to print essential information such as production dates, expiration dates, batch numbers, barcodes, and logos on the packaging.

II. Working Principles of the Horizontal Flow Packing Machine

Film Feeding and Forming

The packaging film, usually in roll form, is fed into the machine through a series of rollers. The film is then guided through a forming tube, where it is shaped into a continuous tube around the product feeding area. The forming process is crucial as it ensures that the film is properly aligned and ready for the next stages of packaging.Product Feeding

Products to be packaged are conveyed into the machine in an organized manner. Depending on the type of product, different feeding mechanisms may be used, such as vibratory feeders for small, irregularly shaped items or belt conveyors for larger, more stable products. The products are spaced evenly to ensure consistent packaging.Sealing and Filling

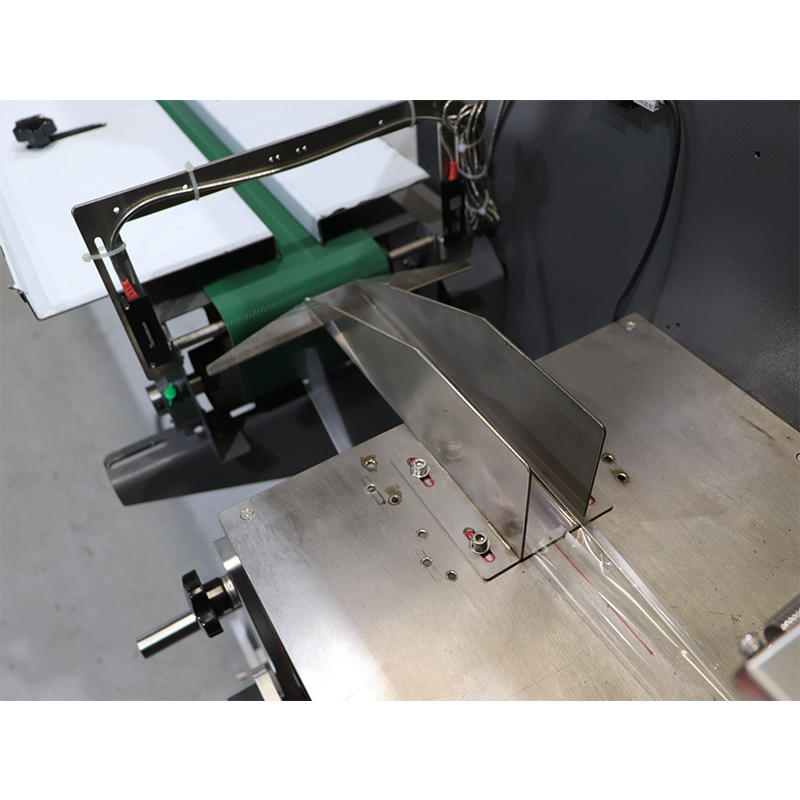

As the products move along the tube of packaging film, the machine performs a longitudinal seal along the edge of the film to create a closed tube. Simultaneously, the products are filled into the tube at the appropriate intervals. This process requires precise synchronization to ensure that each product is accurately placed within the film tube.Cross-Sealing and Cutting

After the products are filled into the tube, the machine performs cross-sealing at regular intervals to create individual packages. The cross-sealing jaws heat and press the film to form a strong seal. Once sealed, the packages are cut into discrete units, ready for further processing or distribution.Coding

During the packaging process, the coding device is activated to print the required information on the packaging material. The coding can be done either before or after the cross-sealing step, depending on the machine's design and the type of coding technology used. The coding device is programmed to print accurate and legible information, ensuring traceability and compliance with regulatory requirements.

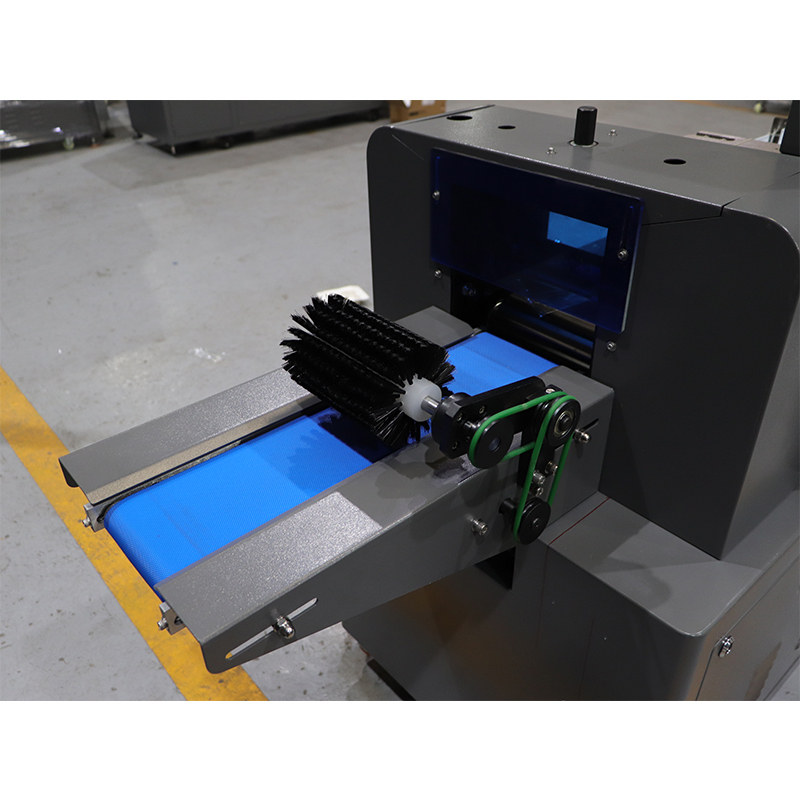

III. Components of the Horizontal Flow Packing Machine with a Coding Device

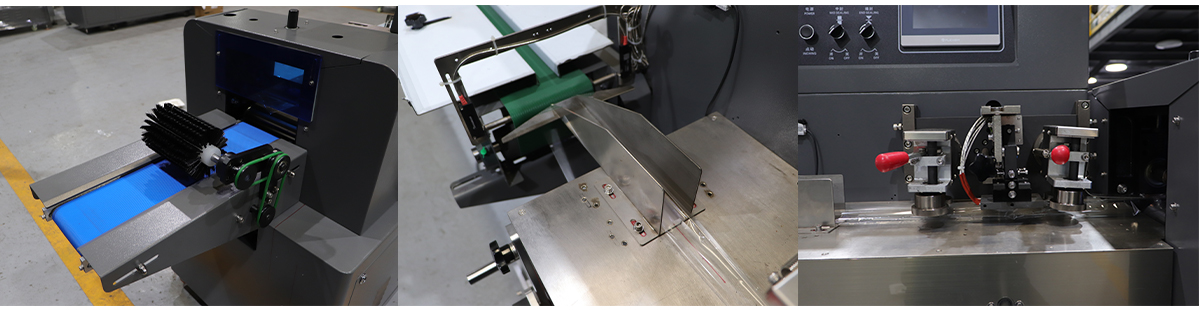

Film Unwinding and Tension Control System

This system ensures that the packaging film is unwound smoothly and maintained at a consistent tension throughout the packaging process. Proper tension control is essential to prevent film wrinkles, misalignment, and other issues that could affect the quality of the packaged products.Forming Tube and Shoulder

The forming tube and shoulder are responsible for shaping the flat packaging film into a tube. They are designed to guide the film accurately and ensure that it forms a uniform tube around the product feeding area.Product Feeding Mechanism

The product feeding mechanism is tailored to the specific type of product being packaged. It can include conveyors, chutes, or other devices that transport the products into the machine in a controlled manner.Sealing System

The sealing system consists of longitudinal and cross-sealing jaws. The jaws are heated to the appropriate temperature to melt and bond the packaging film, creating strong seals. The sealing system is a critical component that directly affects the integrity of the packaged products.Cutting Mechanism

The cutting mechanism is used to separate the filled and sealed packages into individual units. It can be a mechanical blade, a hot knife, or other cutting devices, depending on the machine's design.Coding Device

The coding device is integrated into the machine to print information on the packaging material. It can be connected to a computer or a control system to receive programming instructions and ensure accurate coding.Control System

The control system is the brain of the horizontal flow packing machine. It coordinates all the functions of the machine, including film feeding, product feeding, sealing, cutting, and coding. The control system allows operators to adjust parameters, monitor the packaging process, and troubleshoot any issues that may arise.

IV. Applications of the Horizontal Flow Packing Machine with a Coding Device

Food Industry

In the food industry, the HFFS packing machine with a coding device is widely used to package a variety of products such as snacks, biscuits, chocolates, candies, and frozen foods. The coding device can print expiration dates, batch numbers, and nutritional information on the packaging, ensuring compliance with food safety regulations and providing consumers with essential product details.Pharmaceutical Industry

The pharmaceutical industry requires high precision and strict compliance with regulatory standards. The horizontal flow packing machine with a coding device is used to package tablets, capsules, and other pharmaceutical products. The coding device can print serial numbers, dosage information, and other critical details on the packaging, enabling traceability and preventing counterfeiting.Cosmetic Industry

Cosmetic products such as lipsticks, mascaras, and small skincare items are often packaged using the HFFS packing machine. The coding device can print brand logos, product names, and usage instructions on the packaging, enhancing brand visibility and providing consumers with useful information.Hardware and Electronics Industry

Small hardware components, electronic parts, and accessories can be efficiently packaged using the horizontal flow packing machine. The coding device can print part numbers, barcodes, and other identification information on the packaging, facilitating inventory management and supply chain operations.Stationery Industry

Stationery items like pens, pencils, erasers, and small notebooks are commonly packaged using the HFFS packing machine. The coding device can print product descriptions, prices, and promotional messages on the packaging, attracting consumers and improving sales.

V. Advantages of the Horizontal Flow Packing Machine with a Coding Device

Increased Efficiency

The integration of multiple packaging functions into a single machine, including forming, filling, sealing, cutting, and coding, significantly reduces the packaging time and labor costs. The HFFS packing machine can operate at high speeds, allowing for large-scale production and meeting the demands of high-volume packaging operations.Enhanced Product Quality

The precise control of the packaging process, from film forming to sealing and cutting, ensures consistent and high-quality packaging. The coding device provides accurate and legible information on the packaging, enhancing the overall appearance and professionalism of the packaged products.Versatility

The horizontal flow packing machine with a coding device is highly versatile and can be adapted to package a wide range of products with different shapes, sizes, and packaging requirements. The machine can handle various types of packaging materials, including plastic films, laminates, and aluminum foils.Improved Traceability

The coding device plays a crucial role in improving product traceability. By printing unique identification numbers, batch numbers, and other relevant information on the packaging, manufacturers can track and trace products throughout the supply chain, facilitating recalls if necessary and ensuring consumer safety.Compliance with Regulations

In many industries, regulatory requirements mandate the inclusion of specific information on product packaging, such as expiration dates, ingredients, and safety warnings. The horizontal flow packing machine with a coding device ensures that all necessary information is accurately printed on the packaging, helping manufacturers comply with regulatory standards and avoid penalties.Cost-Effectiveness

Although the initial investment in a horizontal flow packing machine with a coding device may be significant, the long-term cost savings are substantial. The machine's high efficiency, reduced labor requirements, and minimized packaging waste contribute to a lower cost per packaged unit, making it a cost-effective solution for many businesses.

VI. Maintenance and Troubleshooting of the Horizontal Flow Packing Machine with a Coding Device

To ensure the optimal performance and longevity of the horizontal flow packing machine with a coding device, regular maintenance is essential. Here are some key maintenance tasks:

Cleaning

Regularly clean the machine to remove dust, debris, and product residues. Pay special attention to the sealing jaws, cutting blades, and film feeding rollers, as these areas are prone to buildup that can affect the machine's performance.Lubrication

Lubricate moving parts such as gears, bearings, and chains according to the manufacturer's recommendations. Proper lubrication reduces friction, minimizes wear and tear, and extends the lifespan of the machine components.Calibration

Periodically calibrate the machine's sensors, timers, and temperature controllers to ensure accurate operation. Calibration is crucial for maintaining consistent packaging quality and preventing errors in the packaging process.Inspection

Conduct regular inspections of the machine to identify any signs of wear, damage, or misalignment. Replace worn-out parts promptly to prevent further damage and ensure the machine operates smoothly.

VII. Future Trends in Horizontal Flow Packing Machines with Coding Devices

As technology continues to advance, the horizontal flow packing machine with a coding device is expected to evolve to meet the changing needs of the packaging industry. Some future trends may include:

Increased Automation

More advanced automation features, such as robotic product handling and intelligent control systems, will be integrated into the machines to further improve efficiency and reduce human intervention.Enhanced Connectivity

The machines will become more connected, allowing for remote monitoring, data analysis, and real-time adjustments. This connectivity will enable manufacturers to optimize their packaging operations and respond quickly to changing market demands.Sustainability

There will be a greater focus on sustainability, with the development of machines that can handle eco-friendly packaging materials and reduce energy consumption. Manufacturers will be looking for ways to minimize their environmental impact while maintaining high packaging standards.Advanced Coding Technologies

New coding technologies, such as high-resolution inkjet printing and laser marking, will be adopted to provide more durable and high-quality coding on a wider range of packaging materials.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)