Bully Stick Heat Shrink Packaging Solution: Secure, Sanitary, and Shelf-Ready for Pet Chew Products

Introduction

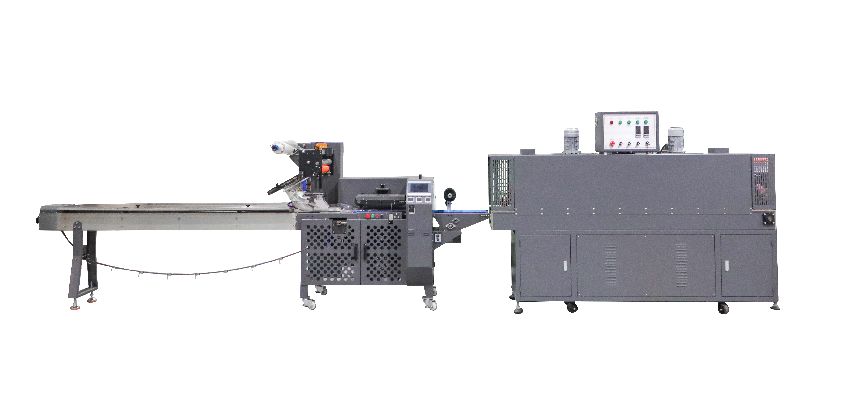

Bully sticks, as a popular form of dog chew, require packaging that not only ensures hygiene and safety but also presents the product attractively on shelves. Heat shrink packaging offers a tight, protective wrap that maintains freshness, prevents contamination, and enhances brand appeal. This article explores the ideal packaging solution for bully sticks using a heat shrink system, particularly a pillow-type shrink packaging line equipped with feeding conveyor, sealing equipment, and shrink tunnel.

Key Features of the Packaging Solution

1. Precise Product Feeding

The system includes a customized conveyor belt with product holders or guides to accommodate the long, irregular shape of bully sticks. This ensures smooth feeding, proper spacing, and stable alignment before sealing.

2. Pillow-Type Film Wrapping

A horizontal pillow-type wrapping machine wraps each bully stick with shrinkable film, forming a tight package that follows the product’s contours. This minimizes air gaps and prevents movement inside the pack.

3. High-Quality Heat Shrink Sealing

Once wrapped, the product moves through a shrink tunnel where controlled hot air shrinks the film uniformly around the bully stick. The result is a wrinkle-free, tamper-evident, and strong package that’s both visually appealing and hygienic.

4. Adaptability for Various Sizes and Configurations

The system supports single-stick packaging, multi-stick packs (e.g., 3–5 sticks), and different shrink film thicknesses and widths. It can be adjusted based on market preferences, from retail display packs to bulk packaging.

5. Food-Grade and Pet-Safe Compliance

All contact parts are made from stainless steel, and the system complies with FDA and CE requirements, making it suitable for packaging edible pet products like bully sticks, jerky chews, and rawhide alternatives.

Working Process Overview

1. Manual or Automatic Loading: Bully sticks are placed onto the feeding conveyor.

2. Film Wrapping: The pillow-type wrapping machine uses a shrink film roll to wrap each unit.

3. Sealing and Cutting: The longitudinal and end seals are formed with precision to enclose the product.

4. Heat Shrinking: The pack passes through a shrink tunnel where hot air shrinks the film uniformly.

5. Cooling and Discharge: The finished pack cools down and is ready for secondary packing or display.

Applications

This packaging solution is not only suitable for bully sticks but also works well for a wide range of dog chews, such as:

Beef tendons

Rawhide rolls

Yak chews

Chicken jerky

Dental sticks

Benefits for Pet Product Manufacturers

Enhanced Product Presentation: Clear, tight shrink wrap highlights product quality and shape.

Extended Shelf Life: Airtight sealing helps preserve freshness and flavor without preservatives.

Improved Hygiene: Sealed packaging protects against dust, bacteria, and handling contamination.

Efficient Automation: Streamlined workflow reduces labor, increases output, and maintains consistency.

Market-Ready Packaging: Attractive, transparent film and smooth finish improve consumer trust and shelf appeal.

Conclusion

For pet treat manufacturers, especially those producing high-protein chews like bully sticks, a heat shrink packaging system offers an excellent combination of protection, efficiency, and visual appeal. Our pillow-type shrink packaging line is designed to meet the specific needs of dog chew products, ensuring hygienic, safe, and market-ready packaging that resonates with today’s pet owners.

Get the latest price? We'll respond as soon as possible(within 12 hours)