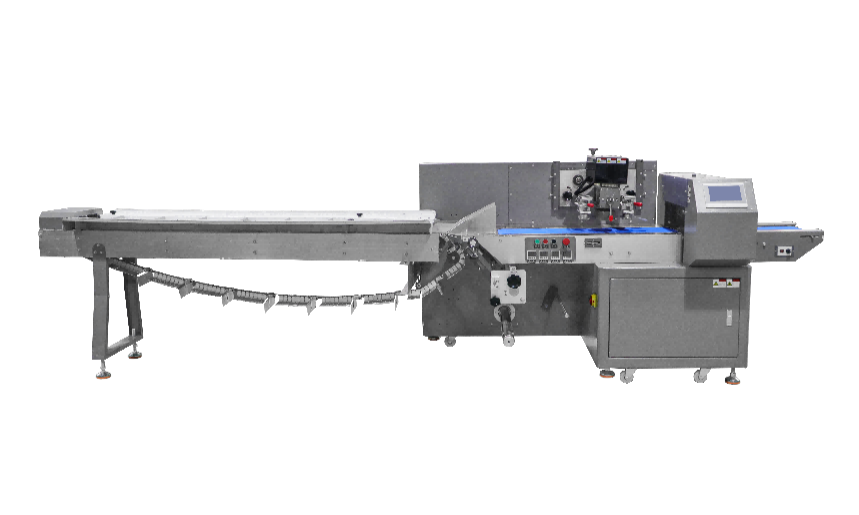

Multi-Spoon Pillow Packing Solution: Accurate Group Packaging with Blocked Conveyor System

In industries such as food, pharmaceutical, and baby product manufacturing, accurate and efficient packaging of small tools like measuring spoons is crucial—especially when multiple units are packed together in one bag. Our multi-spoon pillow packing solution, featuring a blocked conveyor system and horizontal flow wrapper (pillow packaging machine), is specifically designed to meet these demands with high speed, precision, and flexibility.

Key Features

1. Blocked Conveyor Feeding System

The conveyor is equipped with evenly spaced blocking lugs that hold grouped spoons in fixed positions. This ensures stable transportation, avoids misalignment, and allows consistent feeding into the packaging machine.

2. Multi-Spoon Loading Capability

Designed to handle 20, 30, or more measuring spoons per pack depending on product specification and customer requirement. Grouping can be achieved manually, semi-automatically, or through upstream counting and sorting systems.

3. Horizontal Pillow Packing Machine

The pillow packer wraps grouped spoons into a sealed plastic film with airtight sealing, protecting the contents from dust, moisture, and external damage. High-speed operation up to 50-100 packs/min ensures production efficiency.

4. Compact and Hygienic Design

The machine is made of food-grade stainless steel, easy to clean and suitable for hygiene-sensitive products like baby formula accessories, kitchen measuring tools, or medical devices.

5. Adjustable Settings and Intuitive Control

The user-friendly touchscreen interface allows for quick changeover between product types and pack sizes. Film tension, sealing temperature, and pack length are fully adjustable for optimal sealing and material usage.

Working Principle

1. Product Loading

Grouped spoons are manually or automatically placed into the conveyor pockets formed by the block lugs.

2. Conveyor Feeding

The blocked conveyor ensures precise spacing and timing as the grouped products move toward the flow wrapper.

3. Wrapping and Sealing

The pillow packaging machine wraps the grouped spoons in film, seals both ends, and cuts the pack.

4. Output

Finished packs are discharged to a collecting table or downstream system for boxing or carton packing.

Applications

Infant Formula Accessories: Packing multiple baby formula scoops per pack.

Kitchen Measuring Tools: Grouped spoon sets for baking kits or home cooking.

Medical Sampling Spoons: Hygienic and consistent packaging of grouped lab scoops.

Promotional Packs: Multi-item spoon or scoop bundles for retail or promotional use.

Advantages

Accurate Group Packaging: Prevents missing or extra spoons per pack.

Efficient Throughput: Suitable for large-volume production environments.

Compact Footprint: Fits into existing packaging lines with minimal modification.

Cost-Effective: Reduces manual labor and material waste through automation.

Enhanced Presentation: Sealed pillow-style bags improve retail appeal and product hygiene.

Conclusion

For businesses needing reliable, consistent, and high-speed multi-spoon packaging, our blocked conveyor + pillow packer solution is the optimal choice. It ensures exact quantity control, smooth feeding, and professional packaging results—ideal for enhancing both production efficiency and end-user satisfaction.

Get the latest price? We'll respond as soon as possible(within 12 hours)