Understanding Flour Packaging Systems: From Material Behavior to Automated Packaging Solutions

Introduction

Flour is one of the most widely consumed staple ingredients in the global food supply chain, yet it is also one of the most challenging products to package efficiently. As a fine powder with strong flow sensitivity, dust generation, and moisture affinity, flour requires packaging systems that are carefully designed around its physical behavior rather than simply its volume. From small retail bags to mid-sized foodservice packs, the packaging process plays a decisive role in product stability, shelf life, hygiene, and logistical efficiency.

Modern flour packaging typically relies on automated systems that combine controlled dosing, stable conveying, and reliable sealing. Among these, two configurations are most commonly applied: vertical form fill seal systems paired with screw dosing and screw feeding, and premade pouch packaging systems integrated with screw dosing and screw feeding. Each approach reflects a different packaging philosophy shaped by format requirements, production rhythm, and downstream handling expectations.

Key Physical Characteristics of Flour and Their Packaging Implications

Flour behaves differently from granular or particulate products. Its particle size distribution is uneven, and its tendency to absorb moisture can lead to clumping, reduced flowability, and inconsistent dosing if not properly managed. During packaging, flour also generates airborne dust, which can interfere with sealing zones and compromise hygiene if extraction and control are insufficient.

Because of these characteristics, flour packaging systems are typically designed around volumetric consistency rather than free-flow gravity, relying on screw-based metering to regulate fill accuracy. Equally important is the feeding stage, where screw conveyors ensure a continuous, enclosed transfer from bulk storage to the dosing unit, minimizing contamination and environmental exposure.

Vertical Packaging Systems for Flour Applications

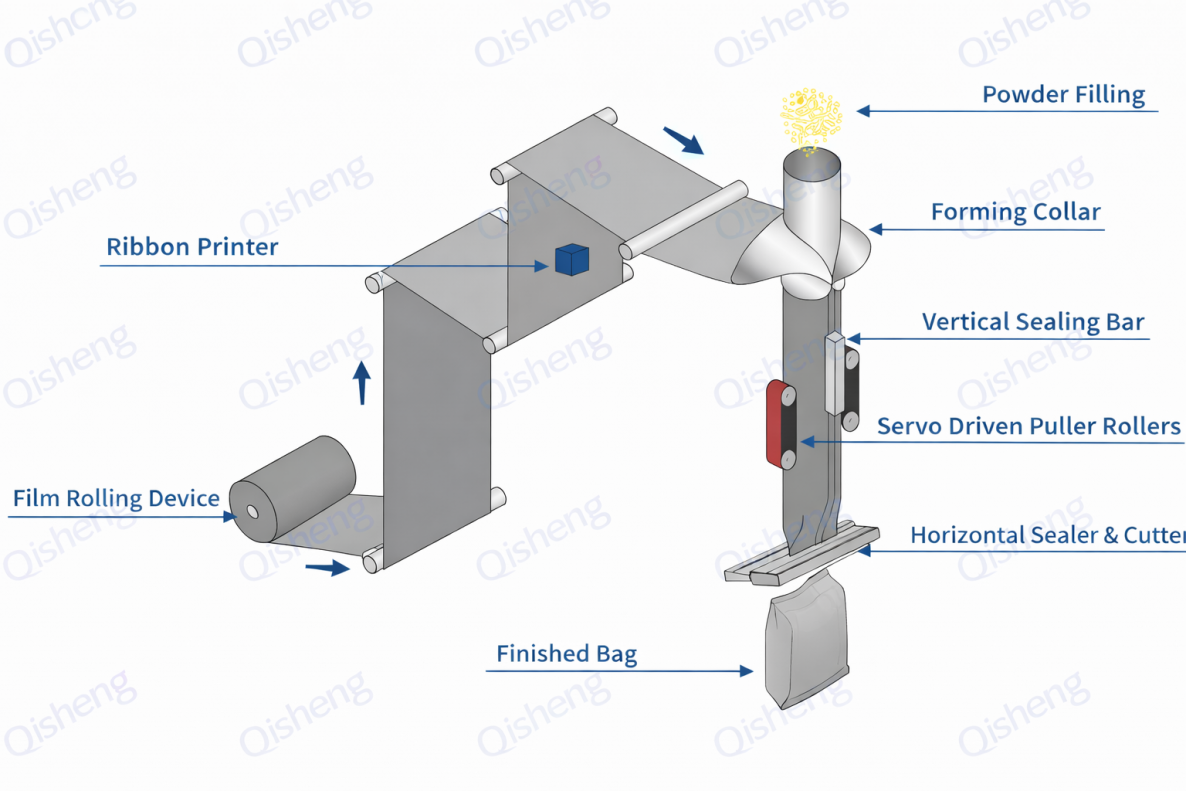

Vertical packaging machines are commonly used for flour due to their compact footprint and continuous production rhythm. In this configuration, flour is conveyed from a hopper via a screw feeder into a screw dosing unit positioned above the forming tube. The screw mechanism meters the flour into a forming bag created from roll film, which is then sealed vertically and horizontally to produce pillow-style or block-bottom packages.

This system is particularly well suited for standardized bag formats such as 200g, 500 g, or 1 kg flour packs. The vertical layout allows gravity-assisted filling once the screw releases the product, while the enclosed forming tube helps guide the powder cleanly into the bag. From an operational perspective, this approach emphasizes production efficiency and material economy, making it common in mills and flour processors supplying high-volume retail channels.

Premade Pouch Packaging for Flour Products

Premade pouch packaging introduces a different structural logic. Instead of forming bags from film rolls, pre-manufactured pouches are picked, opened, filled, and sealed in sequence. When combined with a screw dosing unit and screw feeder, this configuration enables precise flour filling into stand-up pouches, flat pouches, or zipper bags.

This approach is often favored when packaging design, shelf presentation, or resealability is prioritized. Because premade pouches typically have stronger seals and more rigid structures, they are well suited for premium flour products, specialty blends, organic flours, or small-batch formulations. The controlled opening and filling process also reduces dust dispersion around the sealing area, contributing to more consistent seal quality over longer production runs.

Role of Screw Dosing and Screw Feeding in Flour Packaging

Regardless of whether a vertical or premade pouch system is used, screw dosing and screw feeding form the technical core of flour packaging. The screw feeder ensures stable material delivery from bulk storage, while the dosing screw regulates fill quantity with repeatable precision. Unlike gravity-fed systems, screw-based dosing compensates for density fluctuations caused by humidity, milling variation, or aeration.

The synchronization between feeding speed, dosing rotation, and bag handling timing is critical. Properly tuned, this interaction allows flour to be deposited smoothly without surging or backflow, reducing both weight deviation and dust release. From a food safety perspective, the enclosed nature of screw systems also supports cleaner operation and easier compliance with hygiene standards.

Packaging Formats and System Compatibility

Packaging System Configuration | Typical Bag Formats | Key Functional Strengths | Suitable Production Contexts |

Vertical Packaging Machine | Pillow bags, block-bottom bags | High efficiency, low packaging material cost, compact layout | High-volume retail flour, standardized SKUs |

Premade Pouch Packaging Machine | Stand-up pouches, flat pouches, zipper bags | Strong seals, premium presentation, flexible bag design | Specialty flour, organic products, brand-focused packaging |

Operational Considerations and Production Environment

Choosing between vertical and premade pouch packaging for flour is rarely a matter of superiority; it is a matter of alignment with production goals. Vertical systems integrate seamlessly into continuous milling operations where speed, consistency, and cost control are paramount. Premade pouch systems, by contrast, offer adaptability in branding and packaging design, which can be decisive in competitive consumer markets.

Both systems benefit from careful attention to dust management, sealing cleanliness, and screw calibration. In practice, long-term packaging stability is achieved not through aggressive speed targets but through balanced synchronization between feeding, dosing, and bag handling.

Conclusion

Flour packaging is a technically sensitive process shaped by the material’s fine texture, flow behavior, and environmental sensitivity. Whether using a vertical packaging system or a premade pouch packaging system, the integration of screw dosing and screw feeding remains central to achieving accurate fills, clean operation, and reliable seals. By understanding how these systems interact with flour’s physical properties, producers can design packaging lines that prioritize consistency, hygiene, and operational clarity rather than unnecessary complexity.

In this sense, effective flour packaging is less about machinery choice alone and more about respecting the material logic of the product itself.

Get the latest price? We'll respond as soon as possible(within 12 hours)