Stick Pack and Sachet Packaging Solutions: Compact and Efficient VFFS Systems for Small Doses

In industries like food, health supplements, cosmetics, and pharmaceuticals, the demand for convenient, single-use packaging continues to rise. Stick packs and sachets have become the go-to formats for small-dose packaging thanks to their portability, hygiene, and attractive appearance—perfect for today’s fast-paced consumer lifestyle.

To meet these requirements, small vertical form-fill-seal (VFFS) machines offer a compact, cost-effective, and flexible packaging solution. Depending on your production needs, you can opt for single-lane machines or scale up with multi-lane versions for high-output environments.

Stick Packs vs. Sachets: Use Cases and Characteristics

Stick Pack: A slim, tubular-shaped pouch typically used for drink mixes, vitamins, instant coffee, and powdered supplements.

Sachet: A flat, pillow-style pouch suitable for sugar, ketchup, sample cosmetics, pharmaceutical powders, and granules.

Both formats require precise dosing, airtight sealing, and clean-cut finishes to ensure product protection and shelf appeal.

Advantages of Small Vertical Packaging Machines

1. Adaptable to Various Bag Sizes and Formats

The machine can switch between different pouch sizes and film types by changing molds and settings, ideal for diverse product lines.

2. Compatible with Multiple Dosing Systems

Equipped with auger fillers for powders, pumps for liquids, or volumetric cups for granules, these machines handle a wide range of materials with accuracy.

3. Economical Automation for SMEs

Compact design, easy operation, and low maintenance make small VFFS machines ideal for small to mid-scale manufacturers or R\&D labs.

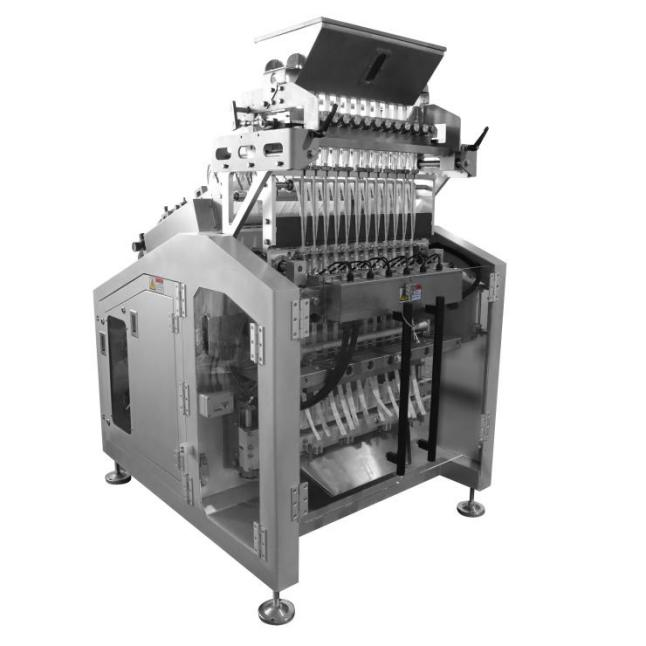

Multi-Lane Stick Pack Machines for High Production Needs

For large-scale Stick Pack production, multi-lane vertical machines dramatically boost productivity. These systems use multiple tracks (typically 8 or 10 lanes) to simultaneously form, fill, and seal Stick Packs at high speeds—ideal for:

Mass production of powdered drink mixes and granules

Contract manufacturing with high SKU turnover

High-demand health and nutrition product packaging

Though more complex, multi-lane machines are highly efficient for large-batch production, offering superior output while maintaining consistency and quality.

Suitable Product Categories

Food Products: Sugar, salt, coffee, seasoning powder, juice concentrates

Nutritional Supplements: Probiotics, vitamin powder, herbal granules

Personal Care: Shampoo, lotion, cleanser, skincare samples

Industrial Use: Desiccants, lubricants, chemical samples

Conclusion

Conclusion

Stick Pack and Sachet packaging are essential for brands seeking to offer single-serve, hygienic, and travel-friendly product formats. Compact vertical packaging machines deliver a reliable, flexible, and scalable solution—whether you’re just starting out or looking to automate a high-throughput production line.

With smart integration, accurate dosing, and stable sealing, both single-lane and multi-lane VFFS systems are critical tools for manufacturers aiming to improve packaging quality, productivity, and market competitiveness.

Get the latest price? We'll respond as soon as possible(within 12 hours)